5 nooc oo kala duwan oo ah mashiinka buuxinta budada auger

1.Miiska miiska

Nooca miiska miiska ee mashiinka buuxinta budada auger waa nooca ugu yar ee shaybaarka. Noocani wuxuu ku habboon yahay buuxinta xawaaraha caadiga ah. Waxa lagu qalay gacanta iyadoo dhalada la saarayo saxanka hoostiisa buuxinta oo ka dhaqaajisa dhalada ka dib marka la buuxiyo. Waxay xamili kartaa xirmo dhalada ama boorsada. Dareemaha ayaa la dooran karaa inta u dhaxaysa hagaajinta dareeraha fargeetada iyo dareeraha sawir-qaadista.

Tilmaamid

| Qaabka | TP-PF-A10 |

| Nidaamka xakamaynta | PLC & Shaashada taabashada |

| Hopper | 11L |

| Culayska Xidhmada | 1-50g |

| Qaadashada miisaanka | By auger |

| Jawaab celinta Miisaanka | Miisaanka khadka ka baxsan (sawirka) |

| Xaqiijinta Xirmada | ≤ 100g, ≤±2% |

| Xawaaraha Buuxinta | 40 - 120 jeer min |

| Bixinta Korontada | 3P AC208-415V 50/60Hz |

| Wadarta Awoodda | 0.84 KW |

| Wadarta Miisaanka | 90kg |

| Guud ahaan Cabbirrada | 590×560×1070mm |

2.Nooc badh-matooto ah

Noocan nus-auto ah ee mashiinka buuxinta budada auger wuxuu ku habboon yahay buuxinta xawaaraha caadiga ah. Waxa lagu qalay gacanta iyadoo dhalada la saarayo saxanka hoostiisa buuxinta oo ka dhaqaajisa dhalada ka dib marka la buuxiyo. Waxay xamili kartaa xirmo dhalada ama boorsada. Dareemaha ayaa la dooran karaa inta u dhaxaysa hagaajinta dareeraha fargeetada iyo dareeraha sawir-qaadista.

Tilmaamid

| Qaabka | TP-PF-A11 | TP-PF-A11S | TP-PF-A14 | TP-PF-A14S |

| Nidaamka xakamaynta | PLC & Shaashada taabashada | PLC & Shaashada taabashada | ||

| Hopper | 25L | 50L | ||

| Culayska Xidhmada | 1 - 500 g | 10 - 5000 g | ||

| Qaadashada miisaanka | By auger | By unugga rarka | By auger | By unugga rarka |

| Jawaab celinta Miisaanka | Miisaanka khadka ka baxsan (sawirka) | Miisaanka khadka tooska ah jawaab celin | Miisaanka khadka ka baxsan (in sawir) | Jawaab celinta miisaanka onlaynka ah |

| Xaqiijinta Xirmada | ≤ 100g, ≤±2%; 100 - 500g, ≤± 1% | ≤ 100g, ≤±2%; 100 - 500g, ≤± 1%; ≥500g,≤±0.5% | ||

| Xawaaraha Buuxinta | 40 - 120 jeer min | 40 - 120 jeer min | ||

| Bixinta Korontada | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | ||

| Wadarta Awoodda | 0.93 KW | 1.4 KW | ||

| Wadarta Miisaanka | 160kg | 260kg | ||

| Guud ahaan Cabbirrada | 800×790×1900mm | 1140×970×2200mm | ||

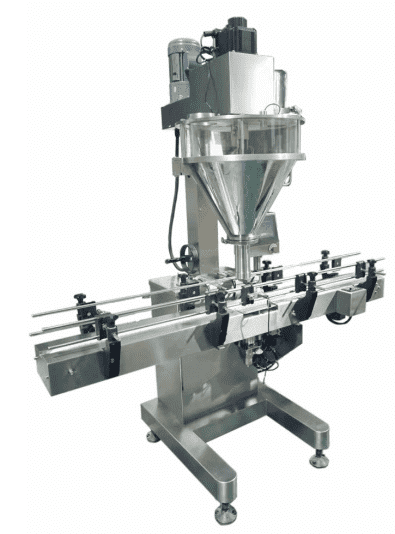

3.Nooca khadka tooska ah

Noocaan tooska ah ee mashiinka buuxinta budada auger wuxuu ku habboon yahay buuxinta dhalada iyo qiyaasta. Gaadhi-qaaduhu si toos ah ayuu dhalada ugu soo shubaa, baakinka dhalada wuxuu hayaa dhalo si uu dhalo-hawlgalaha kor ugu qaado dhalada buuxinta hoosteeda. Ka dib marka dhalooyinka la buuxiyo, qaadiyuhu si toos ah ayuu hore ugu dhaqaajinayaa. Waxay ku xamili kartaa cabbirrada dhalada kala duwan hal mashiin waxayna ku habboon tahay isticmaaleyaasha leh cabbiro badan oo baakad ah. Laba dareemayaal ayaa diyaar ah dareeraha fargeetada iyo dareeraha sawir-qaadista.

Tilmaamid

| Qaabka | TP-PF-A21 | TP-PF-A22 |

| Nidaamka xakamaynta | PLC & Shaashada taabashada | PLC & Shaashada taabashada |

| Hopper | 25L | 50L |

| Culayska Xidhmada | 1 - 500 g | 10 - 5000 g |

| Qaadashada miisaanka | By auger | By auger |

| Jawaab celinta Miisaanka | ≤ 100g, ≤±2%; 100 - 500g, ≤± 1% | ≤ 100g, ≤±2%; 100 - 500g, ≤± 1%; ≥500g,≤±0.5% |

| Xaqiijinta Xirmada | 40 - 120 jeer min | 40 - 120 jeer min |

| Xawaaraha Buuxinta | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Wadarta Awoodda | 1.2 KW | 1.6 KW |

| Wadarta Miisaanka | 160kg | 300kg |

| Guud ahaan Cabbirrada | 1500×760×1850mm | 2000×970×2300mm |

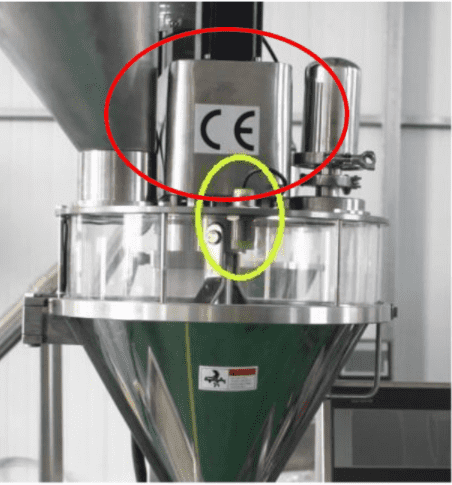

4.Nooc wareeg ah oo toos ah

Nooca wareegtada tooska ah ee xawaaraha sare leh ayaa loo isticmaalaa in lagu shubo budada dhalooyinka. Maadaama giraangiraha dhalada uu qaadan karo kaliya hal dhexroor, mashiinka buuxinta budada ah ee noocaan ah ayaa ugu fiican macaamiisha haysta hal ama laba dhalo dhexroor. Xawaaraha iyo saxnaanta ayaa, guud ahaan, ka weyn kan nooca khadka tooska ah. Waxaa intaa dheer, nooca wareega ee tooska ah waxaa ka mid ah miisaamidda internetka iyo awoodaha diidmada. Buuxiyaha ayaa buuxin doona budada iyadoo loo eegayo culeyska buuxinta waqtiga dhabta ah, shaqada diidmada ayaa aqoonsan doonta oo ka saari doonta miisaan aan u qalmin. Daboolka mashiinka waa ikhtiyaari.

Tilmaamid

| Qaabka | TP-PF-A31 | TP-PF-A32 |

| Nidaamka xakamaynta | PLC & Shaashada taabashada | PLC & Shaashada taabashada |

| Hopper | 35L | 50L |

| Culayska Xidhmada | 1-500g | 10 - 5000 g |

| Qaadashada miisaanka | By auger | By auger |

| Cabbirka weelka | Φ20 ~ 100mm, H15 ~ 150mm | Φ30 ~ 160mm, H50 ~ 260mm |

| Xaqiijinta Xirmada | ≤ 100g, ≤±2% 100 - 500g, ≤±1% | ≤ 100g, ≤±2%; 100-500g, ≤±1% ≥500g,≤±0.5% |

| Xawaaraha Buuxinta | 20 - 50 jeer min | 20 - 40 jeer min |

| Bixinta Korontada | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Wadarta Awoodda | 1.8 KW | 2.3 KW |

| Wadarta Miisaanka | 250kg | 350kg |

| Guud ahaan Cabbirrada | 1400*830*2080mm | 1840×1070×2420mm |

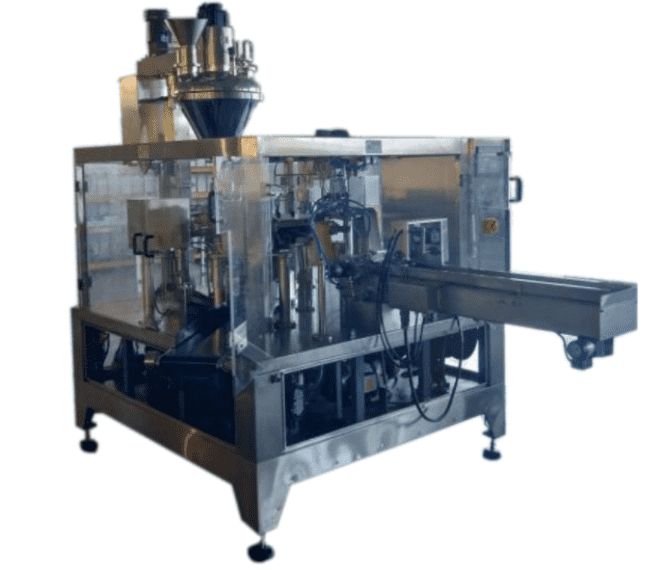

5.Nooca bac weyn

Noocan bacda weyn waxaa loogu talagalay budo yaryar oo soo daaya siigo fiican una baahan xirmo sax ah. Mashiinka noocan oo kale ah wuxuu sameyn karaa cabbirro, laba-buuxinta, shaqo kor-hoos ah iyo wax ka badan. Kuwa soo socdaa waxay ku salaysan yihiin soo-saarka dareen-celinta miisaanka. Way ku fiican tahay buuxinta budada yaryar sida waxyaabaha lagu daro, budada kaarboonka, budada qalalan ee dab damiska, iyo budo kale oo fiican oo u baahan xidhid sax ah.

Tilmaamid

| Qaabka | TP-PF-B11 | TP-PF-B12 |

| Nidaamka xakamaynta | PLC & Shaashada taabashada | PLC & Shaashada taabashada |

| Hopper | Xakamaynta degdega ah ee goynta 70L | Xidhiidhka degdega ah ee 100L |

| Culayska Xidhmada | 100g-10kg | 1-50kg |

| Habka qaadashada | Iyada oo miisaanka internetka; Buuxinta degdega ah oo gaabis ah | Iyada oo miisaanka internetka; Buuxinta degdega ah oo gaabis ah |

| Xaqiijinta Xirmada | 100-1000g, ≤±2g; ≥1000g, ± 0.2% | 1 - 20kg, ≤±0.1-0.2%,>20kg, ≤±0.05-0.1% |

| Xawaaraha buuxinta | 5 - 30 jeer min | 2-25 jeer min |

| Korontada | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Awoodda guud | 2.7 KW | 3.2 KW |

| Wadarta miisaanka | 350kg | 500kg |

| Guud ahaan Cabbirrada | 1030×850×2400mm | 1130×950×2800mm |

Liiska Habaynta ee Nooca Bacda Weyn

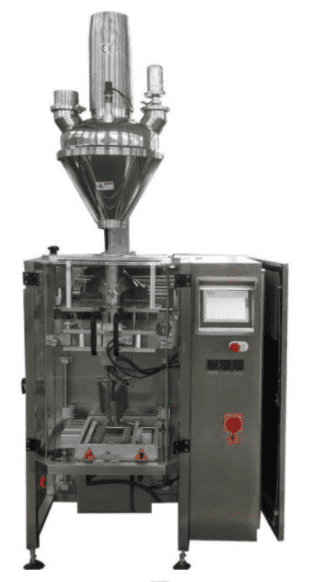

Nidaamka baakadaha budada

Marka mashiinka buuxinta budada auger lagu daro mashiinka wax lagu duubo, mashiinka budada ah ayaa la sameeyay. Waxaa loo isticmaali karaa iyada oo lagu daro mashiinka duubista filimka duuban ee buuxinta iyo mashiinka wax lagu xidho, iyo sidoo kale mishiinka wax lagu xidho ee doypack mini, mishiinka baakadaha rotary, ama mashiinka wax lagu xidho ee hore loo sameeyay.

Sifooyinka gaarka ah ee mashiinka buuxinta budada auger

-Ugur-rogid si aad u hubiso saxnaanta sare ee buuxinta.

- Iyada oo la xakameynayo PLC iyo shaashadda taabashada taabashada oo sahlan in lagu shaqeeyo.

- Auger-ka waxaa wada matoorka servo si uu u bixiyo waxqabad joogto ah.

-Hopper si dhakhso ah ayaa loo gooyaa oo loo nadiifiyaa iyada oo aan la isticmaalin wax qalab ah.

-Mashiinka oo dhan wuxuu ka samaysan yahay bir aan lahayn 304.

-Shaqada miisaanka khadka tooska ah iyo raadraaca saamiga agabka ayaa meesha ka saaraya caqabada buuxinta isbeddelka miisaanka sababtoo ah isbeddelada cufnaanta agabka.

- Wadarta 20 nooc oo cuntooyin ah ku hay codsiga mustaqbalka isticmaal

-Isticmaalka auger cusub si aad ugu xidho walxo kala duwan oo miisaankoodu kala duwan yahay, oo u dhexeeya budo yaryar ilaa qaybo.

- Iyada oo awood u leh in ay diido miisaanka aan heerka sare ahayn.

-Interface luqado badan.

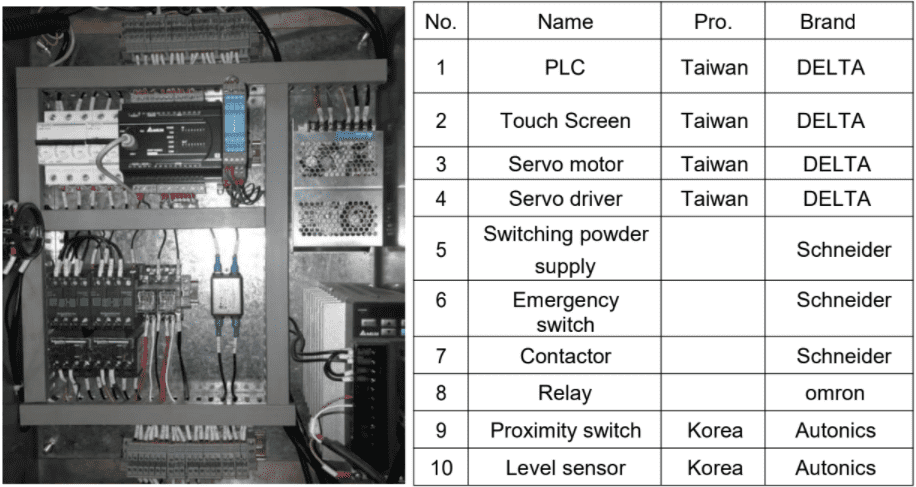

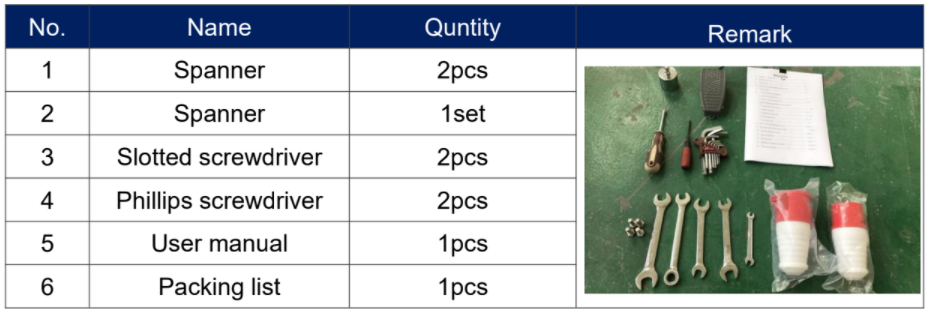

Liiska isku xidhka

Agabka

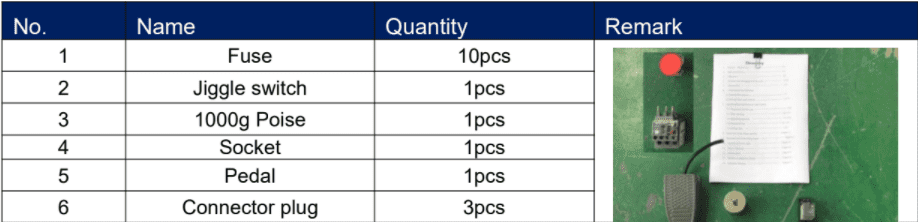

Sanduuqa Qalabka

Qaabka miisaanka

Saxanka buuxinta hoostiisa waxa ku hoos jira unug xamuul oo cabbira miisaanka buuxinta wakhtiga dhabta ah. Si loo gaaro 80% miisaanka buuxinta loo baahan yahay, buuxinta ugu horeysa waa mid degdeg ah oo buuxinaysa. Buuxinta labaad waa mid gaabis ah oo sax ah, iyada oo buuxinaysa 20% soo hadhay iyada oo loo eegayo miisaanka buuxinta koowaad. Saxnaanta qaabka miisaanku waa ka sarreeyaa, laakiin xawaaruhu wuu gaabiyaa.

Macluumaadka mashiinka buuxinta budada Auger

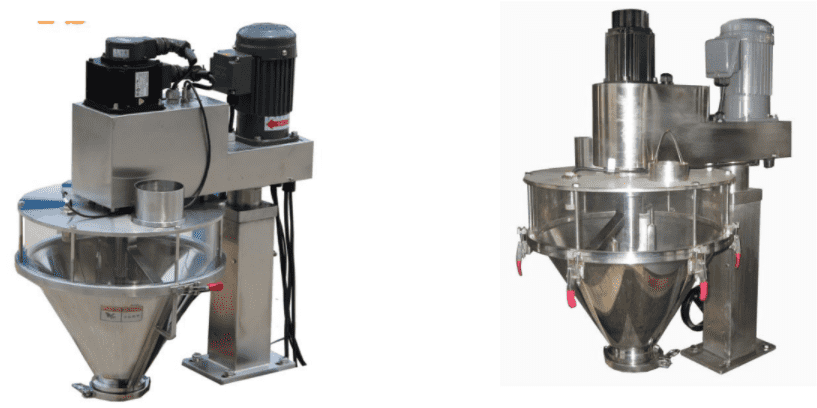

● Hopper Ikhtiyaar ah

Hopper badh furan

Heerarkan kala qaybsanaantu way fududahay in la nadiifiyo oo la furo.

Hopper ka laadlaadsan

Isku darka hopper wuxuu ku haboon yahay budada ganaaxa mana jirto wax ka banaan qaybta hoose ee hopper.

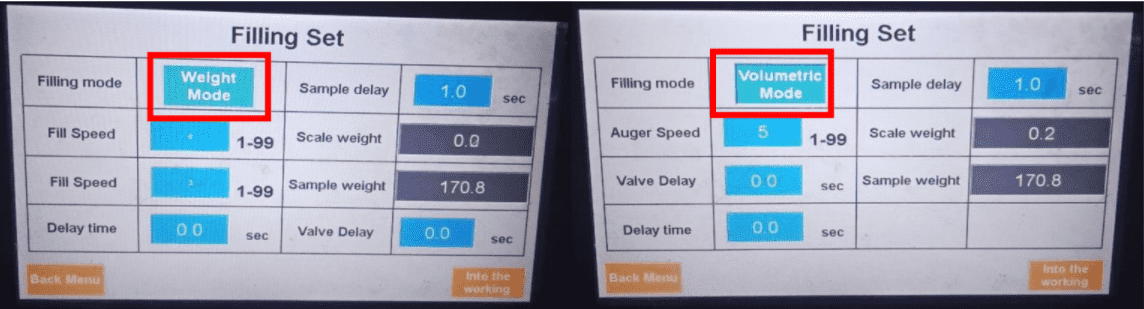

● Habka buuxinta

Qaababka miisaanka iyo mugga waa la bedeli karaa.

Habka codka

Mugga budada ah ee la dhimay iyadoo la rogayo furka hal wareeg ayaa go'an. Koontarooluhu wuxuu qiyaasi doonaa inta wareeg ee uu furku u baahan yahay inuu sameeyo si uu u gaadho miisaanka buuxinta la rabo.

Mashiinka buuxinta budada Augerhab hagaajin

Nooca sharoobada

Ma jiraan wax dalool ah oo laga yaabo in budada ay ku dhuumato, wayna fududahay in la nadiifiyo.

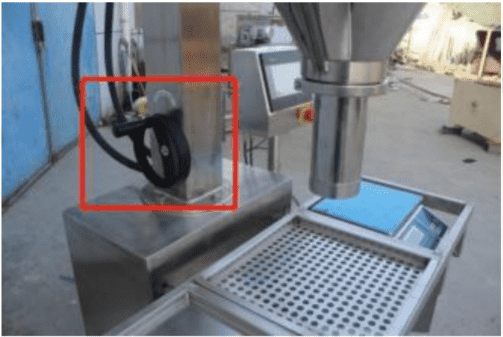

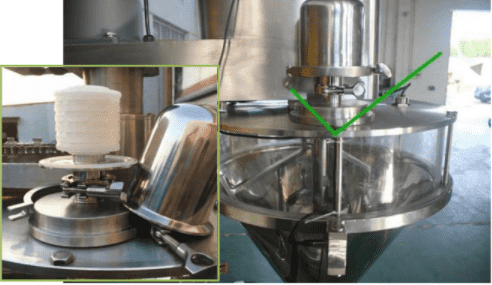

Mashiinka buuxinta budada Augergiraangiraha gacanta

Waxay ku habboon tahay in la buuxiyo dhalooyinka iyo bacaha dhererka kala duwan. Si aad kor ugu qaaddo oo aad hoos ugu dhigto buuxinta adiga oo rogaya giraangiraha gacanta. Haystayaduna waa ka dhumuc weyn tahay oo waa ka sii waarta.

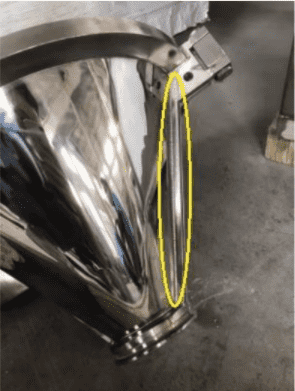

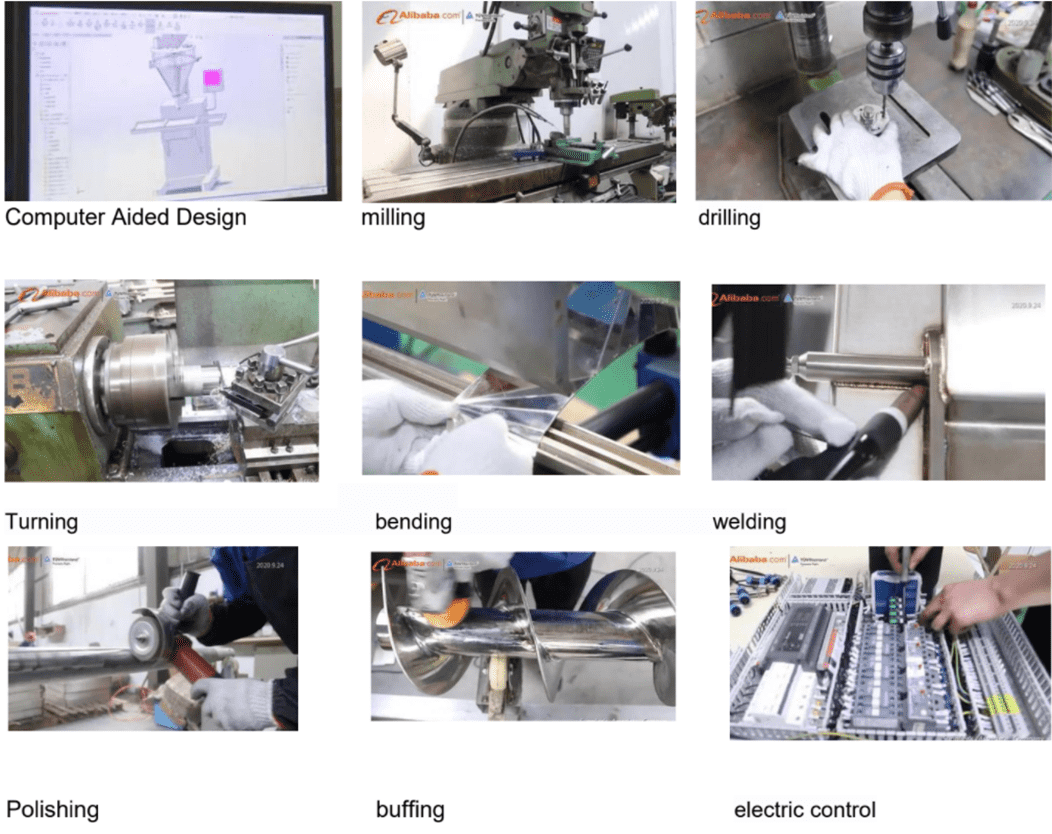

Mashiinka buuxinta budada Augerfarsamaynta

Alxan buuxa oo ay ku jiraan cidhifka hopper oo ay fududahay in la nadiifiyo.

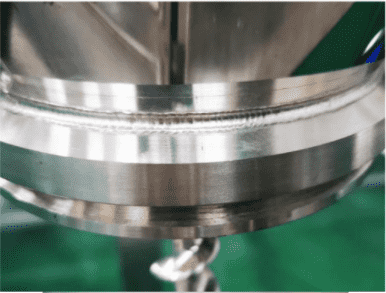

Mashiinka buuxinta budada Augersaldhigga motor

Mashiinka oo dhan, oo ay ku jiraan saldhigga iyo xajiyaha mootada, wuxuu ka samaysan yahay SS304, kaas oo ah walxo waara oo sarreeya.

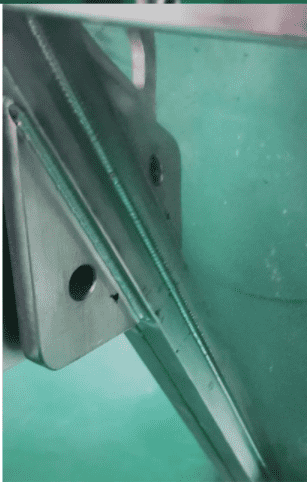

Mashiinka buuxinta budada Augermeel hawada laga saaro

Naqshad gaar ah ayaa loogu talagalay ka hortagga in boodhka uu ku dhaco hopper. Way fududahay in la nadiifiyo oo heer sare ah.

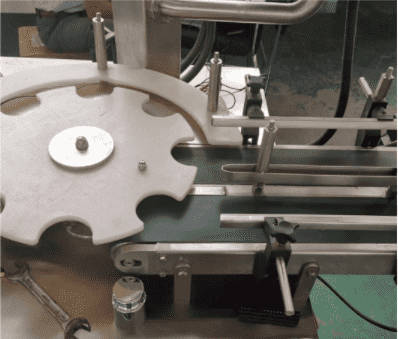

Mashiinka buuxinta budada Augerlaba suunka wax soo saarka

Mid ka mid ah suunka ayaa ururiya dhalooyin miisaan leh, halka suunka kalena uu ururiyo dhalooyin aan miisaan lahayn.

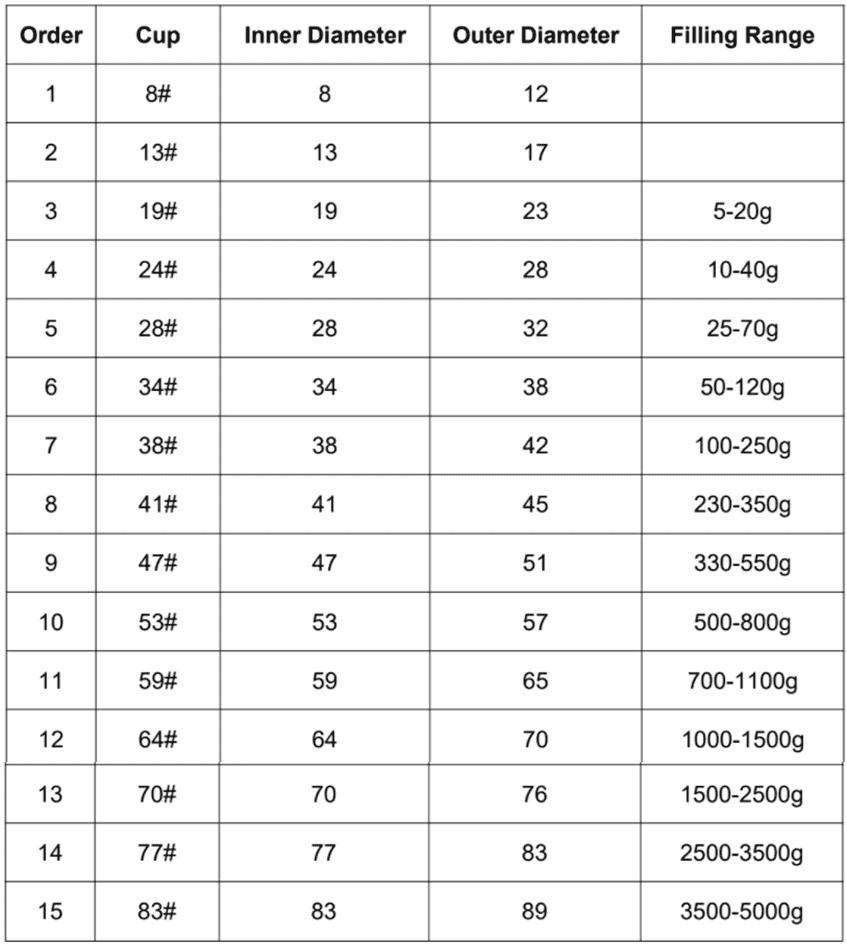

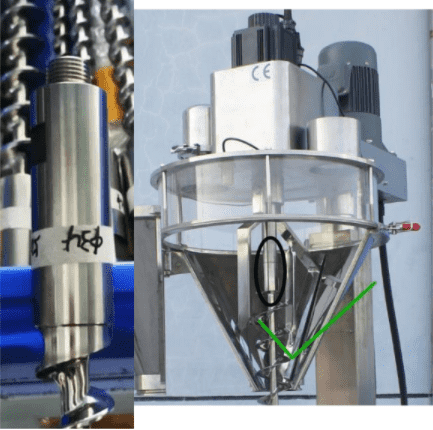

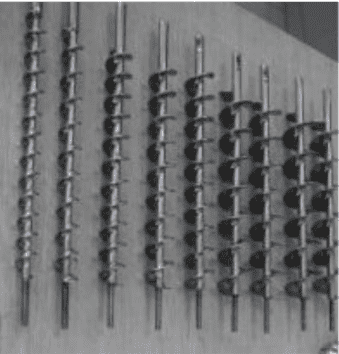

Mashiinka buuxinta budada Augercabbirrada kala duwan ee cabbiraadda auger iyo buuxinta nozzles

Si loo gaaro saxsanaan wanagsanaaday oo waqtiga loo badbaadiyo, qiyaaso kala duwan oo auger ah ayaa loo isticmaali karaa noocyo kala duwan oo miisaan buuxin ah.

Hal xajmigu wuxuu ku habboon yahay hal miisaan oo kala duwan si loo hubiyo buuxinta saxda ah; tusaale ahaan, dhexroorka 38mm wuxuu ku fiican yahay buuxinta 100g-250g.

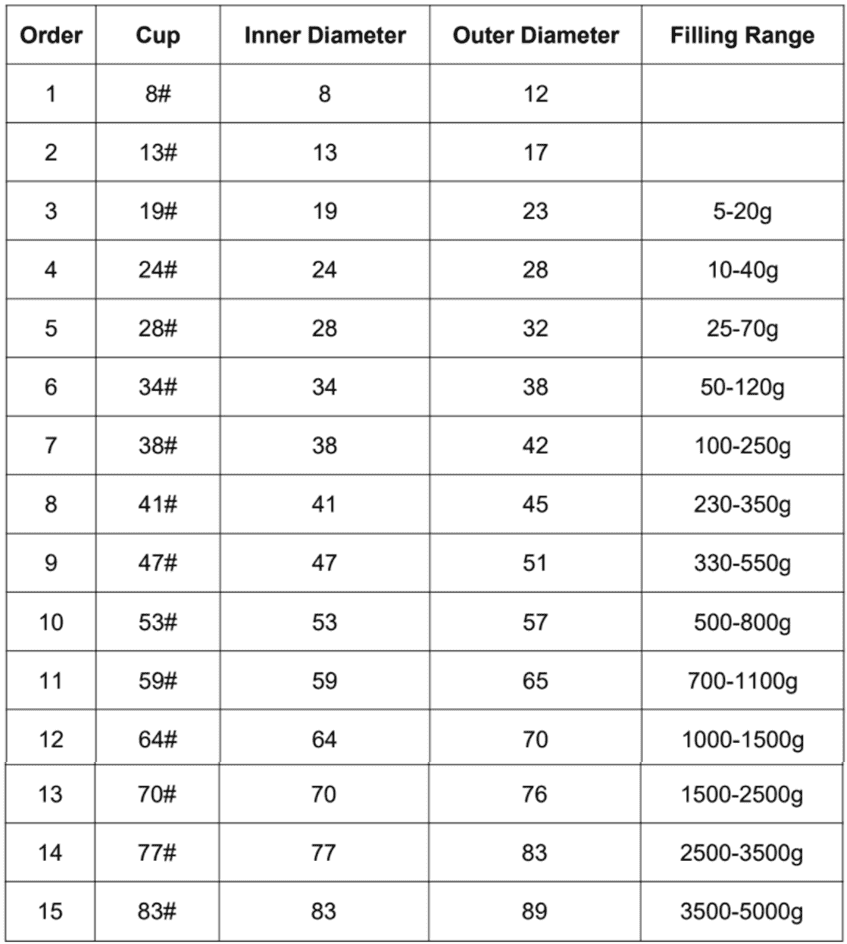

Mashiinka buuxinta budada Augercabbirrada iyo miisaanka buuxinta la xidhiidha

Cabbirrada Koobka iyo Xadka Buuxinta

Haddii aadan hubin cabbirka auger aad u baahan tahay, fadlan nala soo xiriir waxaanan kaa caawin doonaa inaad doorato midka saxda ah.

Mashiinnada La Xiriira:

Isku-dubbaridka quudiyaha shaqadamashiinka buuxinta budada augerMashiinka xidhitaanka boorsada

Boodhka-ururinta ayaa u shaqeeyamashiinka buuxinta budada auger

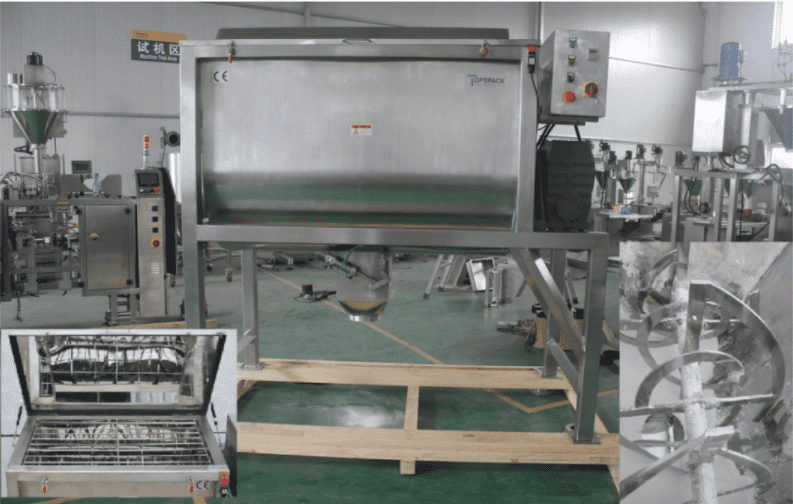

Isku-dhafka Ribbon

Hagaajintamashiinka buuxinta budada auger

Bandhiga Warshada

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur