Video

Sharaxaada guud

TP-TGXG-200 Mashiinka daboolka dhalada ee tooska ah waxaa loo isticmaalaa in lagu xidho koofiyadaha dhalada si toos ah.Waxaa si weyn loogu dabaqaa cuntada, dawooyinka, warshadaha kiimikada iyo wixii la mid ah.Ma jiro wax xaddidan oo ku saabsan qaabka, alaabta, cabbirka dhalooyinka caadiga ah iyo koofiyadaha.Nooca daboolka joogtada ah wuxuu ka dhigayaa TP-TGXG-200 inuu la qabsado xawaaraha khadka xirmada ee kala duwan.Mashiinkaani runtii ujeeddooyin badan buu leeyahay, kaas oo si ballaaran loo isticmaalo oo si sahlan loo isticmaalo.Marka la barbar dhigo nooca shaqada ee soo jireenka ah, TP-TGXG-200 waa wax ku ool aad u sarreeya, cadaadis adag, oo waxyeello yar u geysta koofiyadaha.

Codsiga

Mashiinka daboolka tooska ah waxaa loo isticmaali karaa dhalooyin leh koofiyado kala duwan, qaabab iyo sidoo kale qalab.

A. Cabbirka dhalada

Waxay ku habboon tahay dhalooyinka leh dhexroorka 20-120mm iyo dhererka 60-180mm.Laakiin waxaa lagu habeyn karaa cabbirka dhalada ku habboon ee ka baxsan xadkan sidoo kale.

B. Qaab dhalada

Mashiinka daboolka tooska ah waxaa lagu dabaqi karaa qaabab kala duwan sida qaab wareeg ah ama qaab adag.

C. Dhalo iyo wax dabool ah

Wax kasta oo caagagga galaaska ah ama birta ah, mishiinka daboolka tooska ah ayaa qaban kara dhammaantood.

D. Nooca koofiyadda

Mashiinka daboolka tooska ah wuxuu maroojin karaa dhammaan noocyada fur furka, sida bamka, buufinta, fur furka iyo wixii la mid ah.

E. Warshadaha

Mashiinka daboolka tooska ah wuxuu ku biiri karaa dhammaan noocyada warshadaha iyadoon loo eegin budada, dareeraha, khadka baakadaha granule, ama waa cuntada, daawada, kiimikada ama warshado kale.Meel kasta oo ay jiraan koofiyadaha birta ah, waxaa jira mishiinka daboolka si toos ah loogu shaqeeyo.

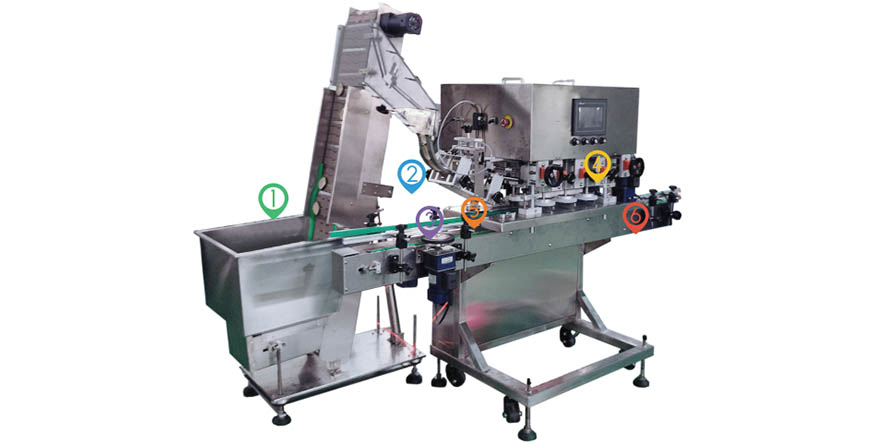

Dhismaha & habka shaqada

Waxay ka kooban tahay mashiinka daboolka iyo furka quudiyaha.

1. Koofida quudiyaha

2. Koofida gelinta

3. Dhalo kala saara

4. Taayirada daboolka

5. Suunka dhalada lagu xiro

6. Suunka gudbinta dhalada

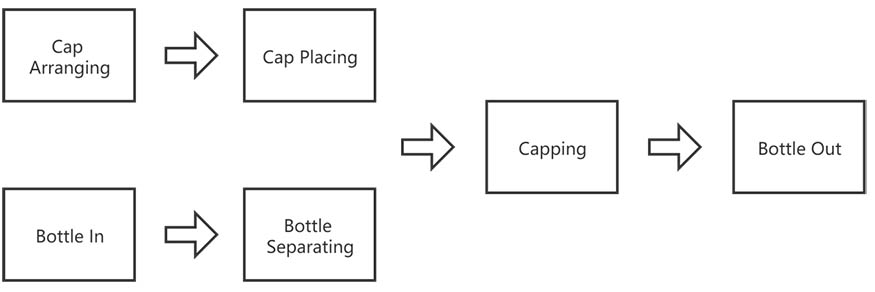

Waxyaabaha soo socda ayaa ah habka shaqada

Astaamaha

■ Si weyn loogu isticmaalo dhalooyinka iyo koofiyadaha qaabab iyo walxo kala duwan leh.

■ PLC & kantaroolka shaashadda taabashada, fududahay in la shaqeeyo.

■ Hawlgal fudud iyo hagaajin fudud, badbaadi ilo aad u badan iyo sidoo kale kharashka waqtiga.

■ Xawaare sare oo la isku hagaajin karo, kaas oo ku habboon dhammaan noocyada xariiqda xirmada.

■ Waxqabad xasilloon oo sax ah oo sarreeya.

■ Hal badhan oo shaqo bilaabaya ayaa keenaya wax badan oo fudud.

■ Naqshad tafatiran ayaa ka dhigaysa mashiinka mid aadaminimo iyo caqli badan.

■ Saamiga wanaagsan ee aragtida mashiinka, naqshadeynta heerka sare iyo muuqaalka.

■ Jirka mashiinka wuxuu ka samaysan yahay SUS 304, oo la kulmay heerka GMP.

■ Dhammaan qaybaha taabashada leh dhalada iyo daboolku waxay ka samaysan yihiin badbaadada alaabta cuntada.

■ Shaashadda dhijitaalka ah ee soo bandhigta si ay u muujiso cabbirka dhalada kala duwan, taas oo ku habboon in la beddelo dhalada (Ikhtiyaarka).

■ Dareemka indhaha si uu u saaro dhalooyinka khaladku daboolan yahay (Option).

■ Aalad kor u qaadaysa oo si toos ah ugu quudinaysa daboolka.

■ Qaybta daboolka soo dhacaysa waxay meesha ka saari kartaa daboolka khaladka ah (hawo fuushan iyo cabbiridda miisaanka).

■ Suunka lagu cadaadiyo daboolka ayaa soo jeeda, si uu daboolka u hagaajiyo meesha saxda ah ka dibna riixo.

Indheer garad

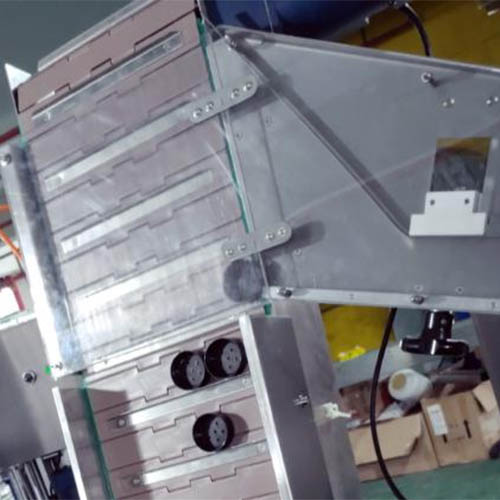

Isticmaal mabda'a dheelitirka dhexe ee kala duwan ee labada dhinac ee daboolka, kaliya fur jihada saxda ah ayaa kor loo qaadi karaa ilaa sare.Daboolka jihada khaldan si toos ah ayuu hoos ugu dhacayaa.

Ka dib marka uu qaaduhu keeno koofiyadaha korka, afuufayaashu waxa ay ku afuufaan koofiyadaha.

Dareemaha daboolka khaladku wuxuu si fudud u ogaan karaa daboolka rogan.Koofiyadaha qaladka tooska ah ka saara iyo dareeraha dhalada, gaadh saamaynta duubista wanaagsan

Kala-soocida dhalada ayaa midba midka kale ka sooci doona dhalooyinka iyadoo hagaajinaysa xawaaraha dhaqdhaqaaqa dhalada ee booskeeda.Dhalooyinka wareegsan waxay caadi ahaan u baahan yihiin hal kala-sooc, dhalooyinka labajibbaaranna waxay u baahan yihiin laba kala-soociyaal iska soo horjeeda.

Qalab la'aanta daboolka ayaa koontaroolaysa quudiyaha furka oo ordaya oo si toos ah u joogsada.Waxaa jira laba dareemayaal oo ku yaal labada dhinac ee track furka, mid si loo hubiyo in jidka uu ka buuxo koofiyadaha, kan kalena si loo hubiyo in jidku madhan yahay.

Wax ku ool ah

Xawaaraha ugu badan ee gudbiyaha dhalada iyo quudiyaha furku wuxuu gaari karaa 100 bpm, kaas oo keenaya mishiinka xawaare sare oo ku habboon khadadka xirmooyinka kala duwan.

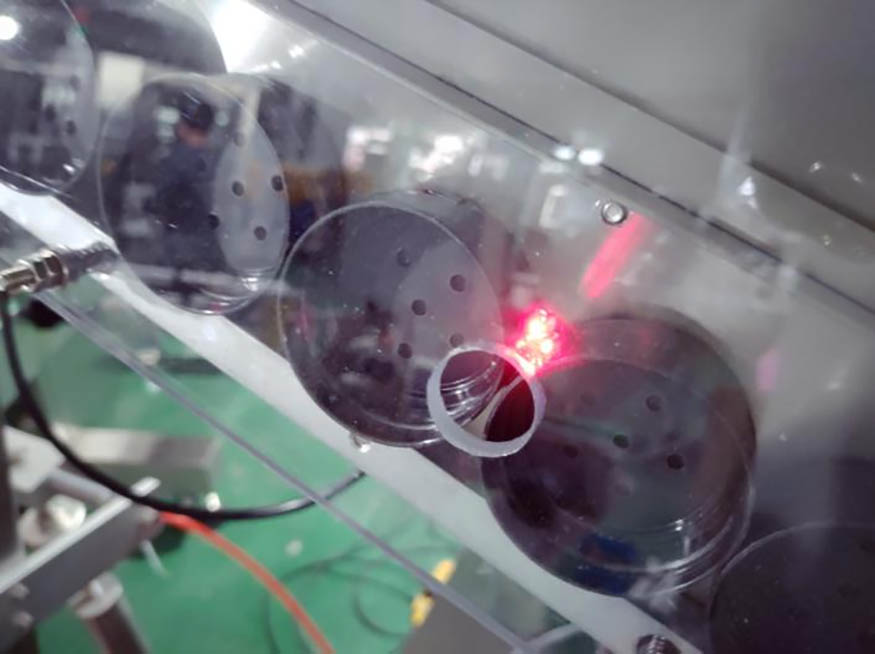

Saddex lammaane oo taayirro ah ayaa si degdeg ah u leexiya furayaasha.Labada lamaane mid kastaa wuxuu leeyahay hawl gaar ah.Lammaanaha ugu horreeya waxay u rogi karaan rogaal celis si ay u dhigaan koofiyadaha adag ee ku jira booskooda saxda ah.Laakiin waxay samayn karaan koofiyadaha hoos u dhigaya si ay u gaadhaan meel ku habboon si degdeg ah iyagoo la socda taayirada lammaanaha labaad marka daboolku caadi yahay.Labada lamaane ee saddexaad wax yar bay isku hagaajiyaan si ay furka u adkeeyaan, markaa xawaarahooda ayaa ugu hooseeya dhammaan taayirrada.

Ku habboon

Marka la barbar dhigo hagaajinta taayirrada gacanta ee alaab-qeybiyeyaasha kale, hal badhan si kor loogu qaado ama loo yareeyo dhammaan qalabka wax lagu duubo ayaa aad ugu habboon.

Afarta wareeg ee bidix ilaa midig ayaa loo istcmaalay in lagu hagaajiyo xawaaraha dhalada qaada, isku xidhka dhalada, koofida koofida iyo kala soocida dhalada.Garaacu wuxuu ku hagi karaa wadayaasha si uu u gaadho xawaaraha ku haboon ee xidhmo kasta oo fudud.

Taayirrada gacanta si aad u beddesho masaafada u dhexeysa labada suunka dhalo si fudud.Waxaa jira laba taayir oo ku yaal labada daraf ee suunka isku dhejinta.Dialku wuxuu u horseedaa hawlwadeenku inuu si sax ah u gaadho meesha saxda ah marka uu beddelayo cabbirrada dhalada.

Dabaasha si loo hagaajiyo masaafada u dhaxaysa taayirada daboolka iyo koofiyadaha.Masaafada u dhow, waxaa sii adkeyn doona daboolka.Dial-ku wuxuu caawiyaa hawlwadeenka inuu helo masaafada ugu habboon ee ku habboon.

Hawl fudud

PLC& kantaroolka shaashadda taabashada leh barnaamij hawl fudud, waxay ka dhigaysaa shaqada mid fudud oo hufan.

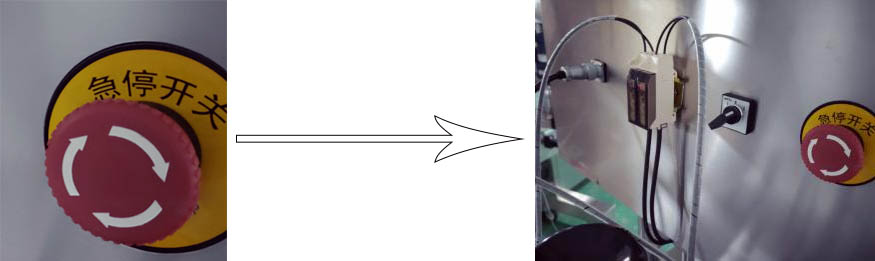

Badhanka degdega ah si aad u joojiso mishiinka hal mar isla markaaba, kaas oo ka ilaalinaya hawlwadeenku in uu ammaan ahaado.

| TP-TGXG-200 Mashiinka daboolka dhalada | |||

| Awood | 50-120 dhalo/daqiiqo | Cabirka | 2100*900*1800mm |

| Dhexroor dhalooyinka | Φ22-120mm (loo habeeyey si waafaqsan shuruudaha) | Dhererka dhalooyinka | 60-280mm (loo habeeyey si waafaqsan shuruudaha) |

| Cabbirka daboolka | Φ15-120mm | Miisaanka saafiga ah | 350kg |

| Heerka u qalma | ≥99% | Awood | 1300W |

| Matrial | birta aan daahin 304 | Voltage | 220V/50-60Hz (ama la habeeyey) |

| Maya | Magaca | Asal ahaan | Summada |

| 1 | leexiyaha | Taiwan | Delta |

| 2 | Shaashada taabashada | Shiinaha | TouchWin |

| 3 | Dareemka indhaha | Kuuriya | Autonics |

| 4 | processor | US | ATMEL |

| 5 | Chip Interface | US | MEX |

| 6 | Ku dhejinta suunka | Shanghai |

|

| 7 | Taxanaha Matoorka | Taiwan | TALIKE/GPG |

| 8 | SS 304 Frame | Shanghai | BaoSteel |

Mashiinka daboolka tooska ah wuxuu la shaqeyn karaa mashiinka buuxinta iyo mashiinka calaamadaynta si loo sameeyo khad xirmo.

A. Dhalada unscrambler+auger buuxinta+mashiinka daboolka otomaatiga ah+mashiinka xidhida bireed.

B. Dhalada unscrambler+auger buuxinta+mashiinka daboolka otomaatigga ah+mashiinka daboolida bireed+mashiinka calaamadaynta

Qalabka ku jira Sanduuqa

■ Buugga tilmaamaha

■ Jaantuska korontada iyo jaantuska isku xirka

■ Hagaha hawlgalka badbaadada

■ Qayb ka mid ah xirashada

■ Qalabka dayactirka

■ Liiska qaabeynta (asalka, moodeelka, faahfaahinta, qiimaha)

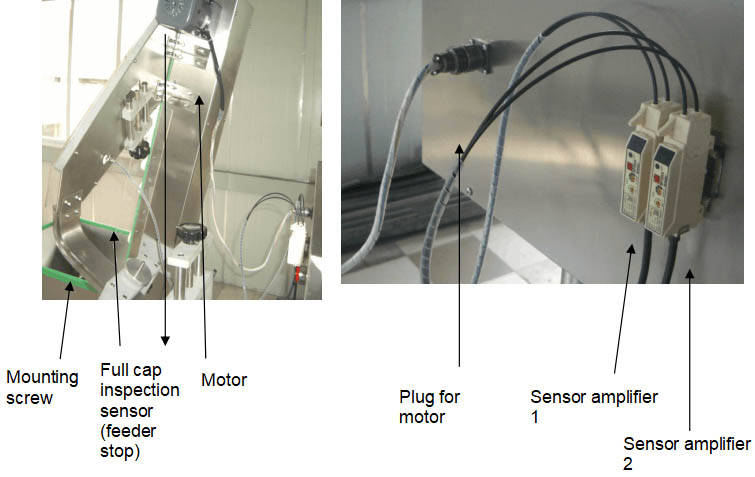

1. Ku rakibida koofiyada wiishka iyo nidaamka gelinta koofiyadda.

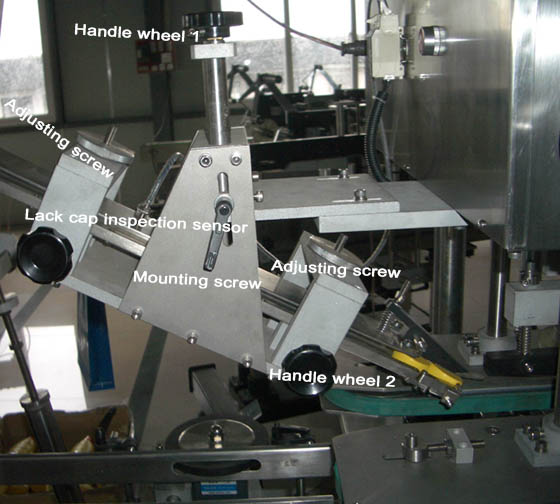

(1) Rakibaadda habaynta furka iyo dareenka ogaanshaha.

Wiishka furka iyo nidaamka meelaynta waa la kala go'ay ka hor inta aan la dhoofin, fadlan ku rakib habaynta furka iyo habka dhejinta mashiinka daboolka ka hor inta aanad socodsiin mishiinka.Fadlan ku xidh nidaamka sida ka muuqata sawirada soo socda:

Dareemaha kormeerka fur la'aanta (mashiinka joogsiga)

a.Ku xidh koofida meelaynta jidka oo ku dheji furka koraya.

b.Ku xidh fiilada matoorka adigoo ku dhejinaya dhinaca midig ee guddiga kantaroolka.

c.Ku xidh dareemaha kormeerka furka buuxa ee cod-weyneeye 1.

d.Ku xidh dareemayaasha kormeerka fur la'aanta iyo cod-weyneeye 2.

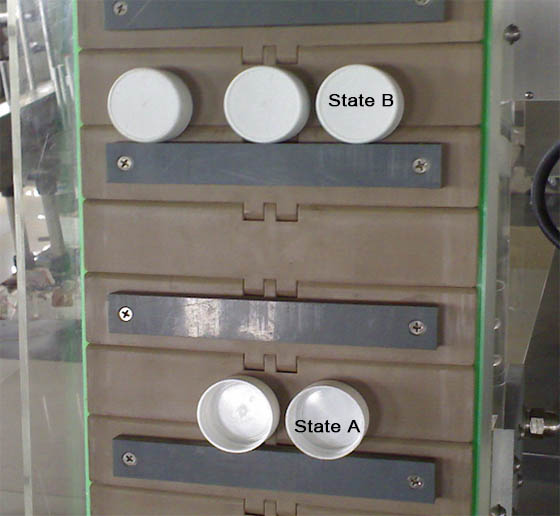

Hagaajin xagasha silsilada fuulista koofida: xagasha silsilada fuulitaanka koofida waxa lagu hagaajiyay si waafaqsan koofiyadda muunada ee aad bixisay ka hor inta aan la rarin.Haddii ay lagama maarmaan tahay in la beddelo tilmaamaha furka (kaliya beddel cabbirka, aan isbeddelin nooca koofiyadda), fadlan ku hagaaji xagasha silsiladda fuulitaanka xagal hagaajinta ilaa silsiladdu ay kaliya kor u qaadi karto koofiyadaha ku tiirsan silsiladda dhinaca sare leh. .Tilmaan sida soo socota:

Daboolka gobolka A waa jihada saxda ah marka silsiladda fuulitaanka koofiyadda ay kor u soo kacayso.

Daboolka gobolka B wuxuu si toos ah ugu dhacayaa taangiga haddii silsiladdu ku taal xagal habboon.

(2) Hagaaji nidaamka tuurista furka (shute)

Xagasha tuurista iyo booska ayaa mar hore loo dejiyay iyadoo loo eegayo muunada la bixiyay.Caadi ahaan haddii aysan jirin qeexid kale oo cusub oo dhalada ama koofiyadda ah, goobta looma baahna in la hagaajiyo.Oo haddii ay jiraan tilmaamo ka badan 1 sifaynta dhalada ama fur, macmiilku wuxuu u baahan yahay inuu liis gareeyo shayga qandaraaska ama ku lifaaqan si loo hubiyo in wax soo saarku uu ka tago meel ku filan oo wax ka beddel ah.Habka hagaajintu waa sida soo socota:

Hagaajin dhererka nidaamka tuurista furka: Fadlan fur furka dhejinta ka hor intaadan leexin shaagagga gacanta 1.

Furaha hagaajinta ayaa hagaajin kara dhererka booska chute.

Shaagagga gacanta ee 2 (labada dhinac) wuxuu hagaajin karaa ballaca meel bannaan.

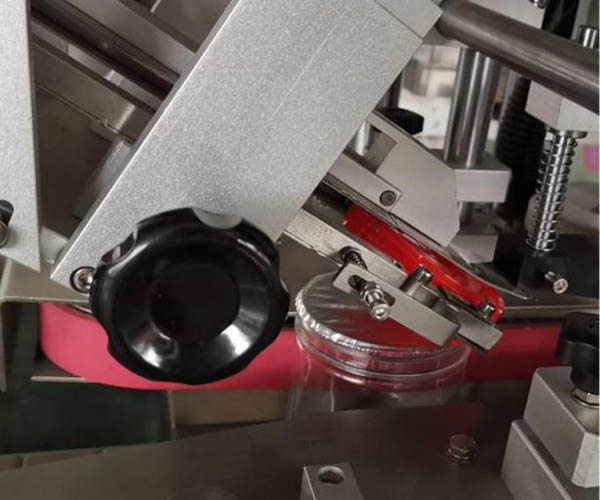

(3) Hagaajinta qaybta riixida furka

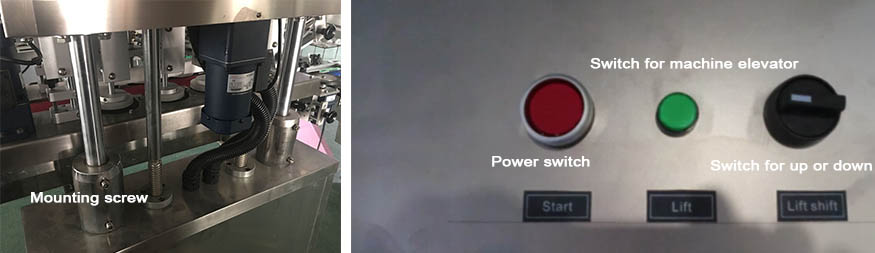

Daboolka ayaa si toos ah u dabooli doona afka dhalada marka ay dhaladu quudinayso aagga qaybta la riixayo.Qaybta riixitaanka furka sidoo kale waa la hagaajin karaa sababtoo ah dhererka dhalooyinka iyo koofiyadaha.Waxay saameyn doontaa waxqabadka daboolka haddii cadaadiska daboolku aanu ku habboonayn.Haddii booska qaybta daboolka daboolku aad u sarreeyo, waxqabadka cadaadiska ayaa saameyn doona.Oo haddii boosku aad u hooseeyo, daboolka ama dhalada ayaa dhaawacmi doona.Sida caadiga ah dhererka qaybta riixitaanka furka ayaa la hagaajiyay ka hor intaan la dhoofin.Haddii isticmaaluhu u baahan yahay inuu hagaajiyo dhererka, habka hagaajintu waa sida soo socota:

Fadlan fur furka dhejinta ka hor inta aanad hagaajin dhererka qaybta riixitaanka.

Waxaa jira qayb kale oo daboolka riixaya oo leh mashiinka si ay ugu habboonaato dhalada ugu yar, habka isbeddelka ayaa lagu muujiyay fiidiyowga.

(4).Hagaajinta cadaadiska hawada si aad furka ugu afuufo godka.

2. Hagaajinta dhererka qaybaha muhiimka ah guud ahaan.

Dhererka qaybaha muhiimka ah sida qaab dhismeedka hagaajinta dhalada, giraangiraha cirridka-elastic, qaybta riixitaanka waxaa lagu hagaajin karaa guud ahaan wiishka mashiinka.Badhanka kantaroolka ee wiishka mishiinku waxa uu ku yaalaa dhinaca midig ee guddiga xakamaynta.Isticmaaluhu waa inuu dabciyaa furka ku dhejinta labada tiir ee taageerada ka hor inta uusan bilaabin wiishka mishiinka.

ø macnaheedu waa hoos iyo ø macnaheedu waa kor.Si loo hubiyo in booska giraangiraha lafdhabarta ay ku habboon yihiin koofiyadaha.Fadlan dami korontada wiishka oo xidh furka korka ka dib hagaajinta.

Fiiro gaar ah: Fadlan riix furaha wiishka (cagaaran) mar walba ilaa aad ka helayso booska saxda ah.Xawaaraha wiishku aad buu u gaabiyaa, fadlan samir u sug.

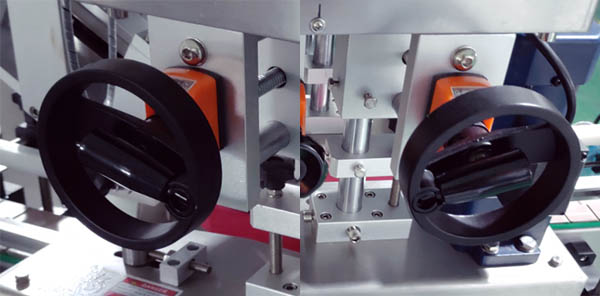

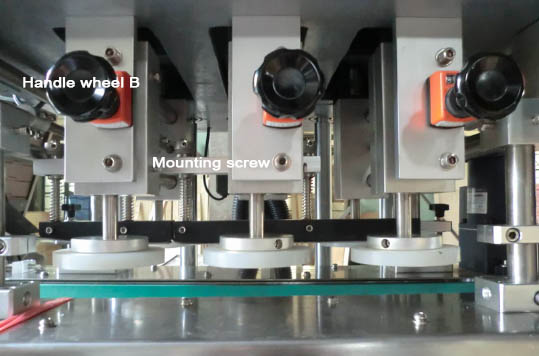

3. Hagaaji giraangiraha lafdhabarta cirridka-elastic (saddex lammaane oo giraangiraha lafdhabarta ah)

Dhererka giraangiraha lafdhabarta waxaa hagaajiya wiishka mashiinka.

Baaxadda lamaanaha giraangiraha ah waxaa lagu hagaajiyaa dhexroorka daboolka.

Caadiyan masaafada u dhaxaysa labada taayir ayaa 2-3mm ka yar dhexroorka furka.Hawlwadeenku waxa uu hagaajin karaa ballaca giraangiraha laftirka ee gacanta giraangiraha B.

Fadlan fur furka wax ku dhejinta ka hor inta aanad hagaajin shaagagga gacanta B.

4. Hagaajinta qaabka hagaajinta dhalada.

Goobta hagaajinta dhalada waxaa lagu hagaajin karaa iyadoo la hagaajinayo booska qaab dhismeedka hagaajinta iyo dhidibka isku xirka.Haddii booska hagaajintu uu aad ugu hooseeyo dhalada, dhaladu way fududahay in la dhigo inta lagu jiro quudinta ama daboolka.Taas beddelkeeda haddii booska hagaajintu uu aad ugu sarreeyo dhalada, waxay carqaladayn doontaa shaqada saxda ah ee giraangiraha lafdhabarta.Hubi in xariiqda udub-dhexaadka ee qalabka wax-qaadista iyo hagaajinta dhalada ay ku yaalaan isla xariiq isku mid ah ka dib hagaajinta.

U rogrogista giraangiraha gacanta A (si aad gacanta ugu rogto 2 gacmood oo wadajir ah) si loo hagaajiyo masaafada u dhaxaysa suunka hagaajinta dhalada.Markaa qaabdhismeedku wuxuu si fiican u hagaajin karaa dhalada inta lagu jiro habka cadaadiska.

Dhererka suunka hagaajinta dhalada waxaa caadi ahaan hagaajiya wiishka mishiinka.

(Ka digtoonow: Hawl-wadeenku wuxuu hagaajin karaa dhererka suunka hagaajinta dhalada gudaha mikro-scope ka dib marka uu furto furka dhejinta ee 4 shaft link.)

Haddii hawlwadeenku u baahdo dhaqaaq suunka hagaajinta oo kala duwan, fadlan hagaaji booska suunka ka dib fur furka 1 oo marooji 2 wada jir ah, oo haddii hawlwadeenku u baahdo hagaajin dhererka suunka oo kala duwan, fadlan fur fur 1 oo keliya, oo rog furka hagaajinta .

5. Hagaajinta booska dhalada hagaajinta taayirrada iyo biraha.

Hawl-wadeenku waa inuu beddelaa booska booska dhalada ee hagaajinta taayirrada iyo biraha marka la beddelayo qeexida dhalada.Inta u dhaxaysa booska hagaajinta giraangiraha iyo biraha waa in 2-3mm ka yar yahay dhexroorka dhalada.Fadlan hubi in xariiqda udub-dhexaadka ee qalabka wax-qaadista iyo hagaajinta dhalada ay ku yaalliin isla xariiq isku mid ah ka dib hagaajinta.

Fure hagaajinta dabacsan waxay hagaajin kartaa booska dhalada hagaajinta giraangiraha.

Xakamaynta hagaajinta dabacsan waxay hagaajin kartaa ballaca biraha ee labada dhinac ee qaadaha.