Qeexid

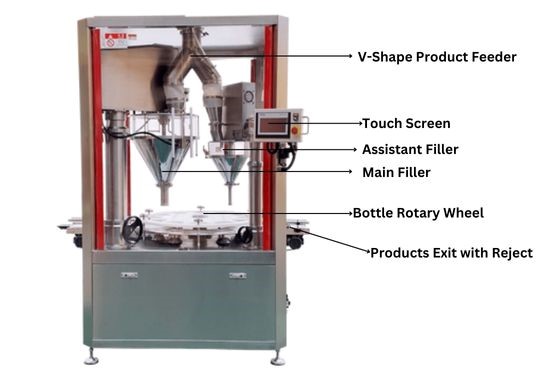

Buuxiyaha budada laba-madaxa ah ayaa buuxiya shuruudaha warshadaha ee ugu dambeeyay waana GMP shahaado. Iyada oo ku saleysan tignoolajiyada baakadaha Yurub, mashiinkani wuxuu bixiyaa qaab adag oo la isku halleyn karo. Kor u kaca sideed iyo laba iyo toban saldhig, xagasha wareega wareega ah ayaa si aad ah hoos loogu dhigay, taasoo keentay in xawliga iyo xasiloonida kor loo qaado. Mashiinku wuxuu u qalabaysan yahay inuu xakameeyo quudinta weelka tooska ah, cabbirka, buuxinta, jawaab celinta miisaanka, sixitaanka tooska ah, iyo hawlaha kale, taasoo ka dhigaysa mid ku habboon buuxinta alaabta budada ah.

Mabda'a Shaqada

- Laba buuxin, mid degdeg ah iyo 80% bartilmaameedka miisaanka iyo kan kale si tartiib tartiib ah u kabo inta soo hartay 20%.

-Laba unug oo xamuul ah, mid ka dib buuxinta degdega ah si loo ogaado inta culeyska buuxinaha gaabiska ah uu u baahan yahay inuu kabo iyo mid ka dambeeya buuxinta gaabiska ah si loo saaro diidmada.

Halabuurka:

Qodobbada ugu muhiimsan waxaa ka mid ah:

1. Shaashadda taabashada, nidaamka xakamaynta PLC, iyo hab hawleed si fudud loo isticmaali karo.

2. Nooca Rotary, laba qaybood oo miisaamaya iyo ogaanshaha, iyo jawaab celinta waqtiga-dhabta ah si loo hubiyo in aan wax cillad ah la soo saarin inta lagu jiro habka baakadaha.

3. Dhalooyinka waxaa si sax ah loogu dhejin karaa jaantuska tooska ah, taasoo keentay dhalo la'aan, buuxin la'aan. Laba qaybood oo ah aaladaha gariirku waxay si wax ku ool ah u yareeyaan mugga walxaha.

4. Naqshadaynta guud ee qaabdhismeedku waa mid macquul ah. Ma jiraan geeso dhintay oo la nadiifiyo. Tilmaamaha weelka si fudud oo degdeg ah ayaa wax looga beddeli karaa.

5. Waxaa loogu talagalay in loo isticmaalo kabitaan labaad ka dib marka la miisaamo si loo hagaajiyo saxnaanta iyo xawaaraha.

6. Diiqa dhalmada iyo hubinta miisaanka ayaa si toos ah u socda. Raad kaabis wareeg ah.

7. Saxeexiyaha meeraha saxda ah, meelaynta saxda ah, iyo saxnaanta sare ee Panasonic servo motor drive screw iyo hawlgalka wareega.

8. Iyada oo weel wax lagu qaado iyo laba qaybood oo gariir iyo qalab dabool boodh ah, si buuxda ayaa loo xidhay oo loo buuxiyey.

Warshadaha Codsiga:

Faahfaahin:

| Habka cabbirka | dheeriga labaad kadib buuxinta |

| Cabbirka weelka | weel cylindrical φ50-130 (badali caaryada) 100-180mm sare |

| Miisaanka xirxirida | 100-1000g |

| Saxnaanta baakadaha | ≤± 1-2G |

| Xawaaraha baakadaha | ≥40-50 dhalooyinka/daqiiqo |

| Korontada | saddex-waji 380V 50Hz |

| Awoodda mishiinka | 5kw |

| Cadaadiska hawada | 6-8kg/cm2 |

| Isticmaalka gaaska | 0.2m3/daqiiqo |

| Miisaanka mashiinka | 900kg |

| Waxyaalo qasacadaysan ayaa la soo diri doona | |

Habaynta:

| Magaca | Summada | Asal ahaan |

| PLC | Siemens | Jarmalka |

| Shaashada taabashada | Siemens | Jarmalka |

| Buuxinta Servo Motor | Hadalka | Taiwan |

| Buuxinta Servo Drive | Hadalka | Taiwan |

| Isku-dhafka Matoorka | CPG | Taiwan |

| Rotary Servo Motor | Panasonic | Japan |

| Rotary Servo Drive | Panasonic | Japan |

| Rotary Precision Planetary Reducer | Mdun | Taiwan |

| Gaadhi-qaade | GPG | Taiwan |

| jabiye | Schneider | Faransiiska |

| Xiriiriyaha | Schneider | Faransiiska |

| Gudbinta Dhexdhexaadka ah | Schneider | Faransiiska |

| Culayska kulaylka | Schneider | Faransiiska |

| Silinder hawada | AirTAC | Taiwan |

| Valve Magnetic | AirTAC | Taiwan |

| Kala soocida saliidda biyaha | AirTAC | Taiwan |

| Dareemiyaha Heerka Walxaha | Autonics | Kuuriyada Koonfureed |

| Dareemiyaha Badbaadada heerka Maadiga | Bedook | Jarmalka |

| Dareemaha korantada | Bedook | Jarmalka |

| Unug raran | METTLER TOLEDO | USA |

Faahfaahin:

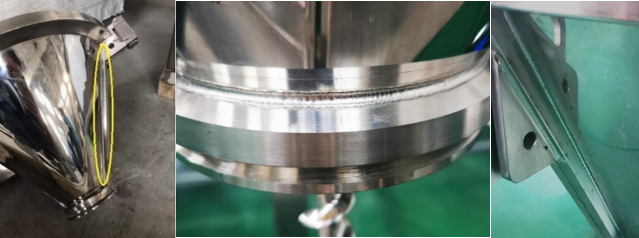

Hopper badh-furan

Heerarkan kala qaybsanaantu way fududahay in la furo oo la ilaaliyo.

Hopper laalaada

Hopper-ka la isku daray wuxuu ku habboon yahay budada aadka u fiican sababtoo ah ma jirto wax farqi ah oo ku yaal qaybta hoose ee hopper.

Nooca Daaqadaha

Ma jiraan wax dalool ah oo budada ah si ay ugu dhuuntaan, nadiifintana waa sahlan tahay.

Mashiinka oo dhan, oo ay ku jiraan saldhigga iyo xajiyaha mootada, wuxuu ka samaysan yahay SS304, kaas oo ka xoog badan oo tayo sare leh.

Nadiifinta way fududahay alxanka buuxa, oo ay ku jirto cidhifka hopper.

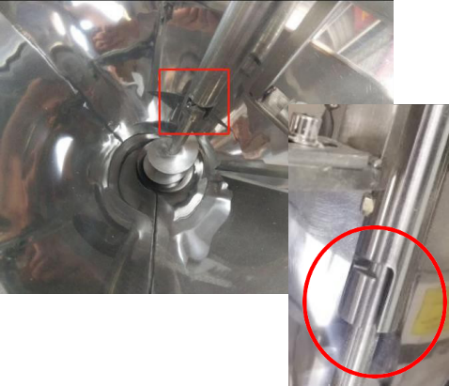

Buuxiyaha labada madax

1. Buuxiyaha aasaasiga ah wuxuu si degdeg ah u gaari doonaa 85% miisaanka la beegsanayo.

2. Buuxiyaha kaaliyaha ayaa si sax ah oo tartiib tartiib ah u bedeli doona bidix 15%.

3. Waxay ka wada shaqeeyaan sidii ay u gaari lahaayeen xawaare sare iyagoo ilaalinaya saxnaanta.

Gariir & miisaan

1. Gariirku waxa uu ku xidhan yahay qaboojiyaha waxa uu ku yaalaa inta u dhaxaysa laba buuxin.

2. Laba unug oo xamuul ah, oo lagu tilmaamay fallaadho buluug ah, ayaa go'doonsan gariir oo ma saameyn doonaan saxnaanta. Midka kowaad wuxuu miisaamaa miisaanka hadda jira ka dib buuxinta koowaad ee ugu weyn, kan labaadna wuxuu go'aamiyaa in badeecada ugu dambeysa ay gaartay miisaanka bartilmaameedka.

Diid dib u warshadaynta

Ka hor inta aan la aqbalin sahayda labaad, diidmada dib ayaa loo warshadayn doonaa waxaana lagu dari doonaa khadadka qasacadaysan.

Marka loo eego mabda'a buuxinta auger, mugga budada ah ee uu hoos u dhigay auger-ka hal goobada ayaa go'an. Natiijo ahaan, cabbirrada auger kala duwan ayaa loo isticmaali karaa si loo gaaro saxsanaan sare oo waqti lagu badbaadiyo kala duwanaanta miisaanka buuxinta. Waxaa jira tuubo auger ah cabbir kasta oo auger ah. Tusaale ahaan, dia. Kaashashka 38mm wuxuu ku habboon yahay buuxinta 100g-250g weel.

Alaab-qeybiyeyaal kale:

Nooca Hang

Budada ayaa lagu qarin doonaa gudaha qaybta isku xirka, taas oo adkeynaysa in la nadiifiyo oo la wasakheeyo xitaa budo cusub.

Meesha alxanka waxaa ka banaan meel bannaan marka aysan jirin alxanka buuxa, kaas oo ay fududahay in la qariyo budada, ay adagtahay in la nadiifiyo, lagana yaabo in ay wasakhayso walxo cusub.

Haysta matoorku maaha mid ka samaysan birta 304.

Cabbirka Koobka iyo Xadka Buuxinta

| Dalbo | Koob | Dhexroorka Gudaha | Dhexroorka dibadda | Buuxinta Range |

| 1 | 8# | 8mm | 12mm | |

| 2 | 13 # | 13mm | 17mm | |

| 3 | 19 # | 19mm | 23mm | 5-20g |

| 4 | 24# | 24mm | 28mm | 10-40g |

| 5 | 28# | 28mm | 32mm | 25-70g |

| 6 | 34# | 34mm | 38mm | 50-120g |

| 7 | 38# | 38mm | 42mm | 100-250g |

| 8 | 41 # | 41mm | 45mm | 230-350g |

| 9 | 47# | 47mm | 51mm | 330-550g |

| 10 | 53# | 53mm | 57mm | 500-800g |

| 11 | 59# | 59mm | 65mm | 700-1100g |

| 12 | 64# | 64mm | 70mm | 1000-1500g |

| 13 | 70# | 70mm | 76mm | 1500-2500g |

| 14 | 77# | 77mm | 83mm | 2500-3500g |

| 15 | 83# | 83mm | 89mm | 3500-5000g |

Habaynta Waxsoosaarka:

Xogta Shirkadda:

Shahaadooyinka:

FAQ:

1. Ma tahay soo saaraha buuxinta xabagta?

Shanghai Tops Group Co., Ltd. waa hormuudka soo saaraha buuxinta auger gudaha Shiinaha oo leh in ka badan toban sano oo waayo-aragnimo ah warshadaha mashiinka wax lagu xidho.

2. Buuxiyaha auger-kaaga CE shahaado miyuu yahay?

Buuxiyaha kaliya ma haysto shahaadada CE, laakiin sidoo kale dhammaan mashiinadayada.

3. Mudo intee le'eg ayay ku qaadanaysaa buuxinta auger inuu yimaado?

Waxay qaadataa 7-10 maalmood si loo soo saaro moodal caadi ah. Mashiinkaaga habaysan waxa lagu dhamayn karaa 30-45 maalmood.

4. Waa maxay adeegga shirkaddaada iyo siyaasadda dammaanadda?

ADEEG NOLOL-DHEER, DAMMAANAD LABAAD AH, DAMMAANAD MATOORKA SADEX SANO (Adeegga dammaanadda waa la sharfin doonaa haddii waxyeeladu aanay sababin qof ama hawl-gal aan habboonayn.)

Ku bixi qaybaha kaabayaasha ah qiimo macquul ah.

Cusbooneysii qaabeynta iyo barnaamijka si joogto ah

Adeega goobta ama adeega fiidyaha onlaynka ah ee ka jawaaba su'aal kasta 24 saacadood gudahood

Waxaad ka dooran kartaa shuruudaha lacag-bixinta ee soo socda: L/C, D/A, D/P, T/T, Western Union, Money Gram, iyo PayPal.

Waxaan aqbalnaa dhammaan shuruudaha qandaraaska ee dhoofinta, sida EXW, FOB, CIF, DDU, iyo wixii la mid ah.

5. Ma awoodaa inaad qaabayso oo aad soo jeediso xalal?

Waxaan leenahay koox naqshadeeye xirfad leh iyo injineer khibrad leh, dabcan. Sheekada rootiga ee Singapore, tusaale ahaan, waxaanu nashqadnay khadka soo saarista caanaha rootiga.

6. Waa maxay noocyada alaabooyinka uu buuxin karo auger-ka?

Waxay xamili kartaa dhammaan noocyada budada ama granule-ka miisaanka iyo buuxinta waxaana si weyn loogu isticmaalaa cuntada, dawooyinka, kiimikooyinka, iyo warshadaha kale.

7. Sidee buu u shaqeeyaa buuxinta auger?

Mugga budada ah ee la dhimay iyadoo la rogayo furka hal wareeg ayaa go'an. Koontarooluhu wuxuu xisaabin doonaa inta wareeg ee ay tahay inuu furku sameeyo si uu u gaaro miisaanka buuxinta bartilmaameedka.