Hordhac

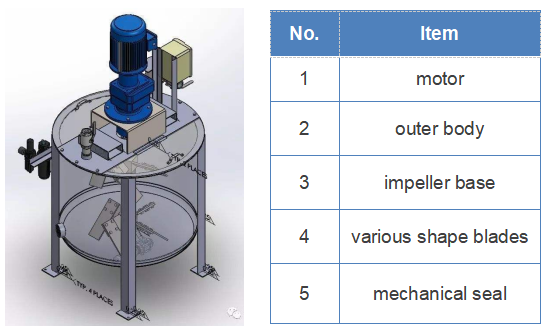

Isku-darka dareeraha ah waxaa loogu talagalay kicinta xawaaraha-hoose, fidinta sare, kala dirida, iyo isku darka dareeraha iyo alaabooyinka adag ee leh muuqaalo kala duwan. Waxay si gaar ah ugu habboon tahay emulifying farmashiyaha, isqurxinta, iyo alaabada kiimikaad ee wanaagsan, gaar ahaan kuwa leh viscosity sare iyo nuxur adag. Qaabdhismeedka: Mashiinkan waxaa ku jira dheriga emulsifying ugu weyn, dheriga biyaha, dheriga saliidda, iyo qaab-shaqo.

Mabda'a shaqada

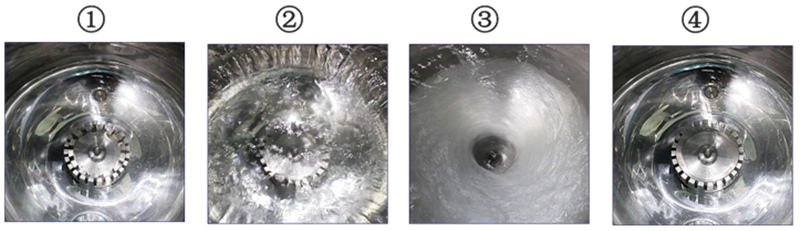

Matoorku waxa uu u shaqeeyaa sidii qayb wadista si uu u dhaqaajiyo shaagagga saddexagalka ah si uu u wareego. Maaddooyinka si fiican ayaa loo walaaqay, la isku daray, oo si isku mid ah loo walaaqay iyadoo la isticmaalayo xawaaraha la hagaajin karo ee walaaqaya suufka dheriga iyo homogenizer-ka hoose. Nidaamku waa mid fudud, buuq yar, oo deggan.

Codsiga

Isku-darka dareeraha ah ayaa lagu dabaqaa warshado badan, sida dawooyinka, cuntada, daryeelka shakhsi ahaaneed, waxyaalaha la isku qurxiyo, iyo warshadaha kiimikada.

Warshadaha dawooyinka: sharoobada, boomaatada, dareeraha afka iyo qaar kaloo badan

Warshadaha cuntada: saabuunta, shukulaatada, jelly, cabitaanka iyo qaar kaloo badan

Warshadaha daryeelka shakhsi ahaaneed: shaambo, qubeyska, nadiifiyaha wejiga iyo qaar kaloo badan

Warshadaha qurxinta: kiriimyada, hadhka indhaha dareeraha ah, qurxinta qurxinta iyo qaar kaloo badan

Warshadaha kiimikada: rinjiga saliidda, rinjiga, xabagta iyo qaar kaloo badan

Astaamaha

- Isku-darka maaddada sare ee viscosity waxay ku habboon tahay wax soo saarka ballaaran ee warshadaha.

- Naqshadeynta gaarka ah ee daabka wareega waxay hubisaa in maaddada viscosity sare kor iyo hoos loo qaado iyada oo aan meelna lahayn.

- Qaabka xiran wuxuu ka hortagi karaa siigada cirka sabbaynaysa, habka faakuumka sidoo kale waa la heli karaa.

Tilmaamid

| Qaabka | Wax ku ool ah mugga (L) | Cabirka haanta (D*H)(mm) | Wadarta Dhererka (mm) | Matoorka awood (kw) | Xawaaraha kicinta (r/daqiiqo) | |

| TPLM-500 | 500 | Φ800x900 | 1700 | 0.55 | 63 | |

| TPLM-1000 | 1000 | Φ1000x1200 | 2100 | 0.75 | ||

| TPLM-2000 | 2000 | Φ1200x1500 | 2500 | 1.5 | ||

| TPLM-3000 | 3000 | Φ1600x1500 | 2600 | 2.2 | ||

| TPLM-4000 | 4000 | Φ1600x1850 | 2900 | 2.2 | ||

| TPLM-5000 | 5000 | Φ1800x2000 | 3150 | 3 | ||

| TPLM-6000 | 6000 | Φ1800x2400 | 3600 | 3 | ||

| TPLM-8000 | 8000 | Φ2000x2400 | 3700 | 4 | ||

| TPLM-10000 | 10000 | Φ2100x3000 | 4300 | 5.5 | ||

| Waxaan u habeyn karnaa qalabka sida waafaqsan shuruudaha macaamiisha. | ||||||

| Xaashida xogta haanta | ||||||

| Qalab | 304 ama 316 bir ah oo aan lahayn | |||||

| Dahaarka | Lakab keli ah ama leh dahaar | |||||

| Nooca Madaxa Sare | Dusha sare ee saxanka, Fur daboolka sare, korka fidsan | |||||

| Nooca hoose | Qeybta hoose ee saxanka, gunta koonida ah, Hoose fidsan | |||||

| Nooca kicinta | impeller, Barroosin, Turbine, xiirid sare, qase magnetic, qasiyaha barroosin leh xoqid | |||||

| qasiyaha birlabeedka, qasiyaha barroosinka oo leh xoqoxo | ||||||

| Gudaha finsh | Muraayada ayaa la safeeyey Ra <0.4um | |||||

| Dhammaadka dibadda | 2B ama Satin dhammayn | |||||

Habaynta caadiga ah

Sawirro faahfaahsan

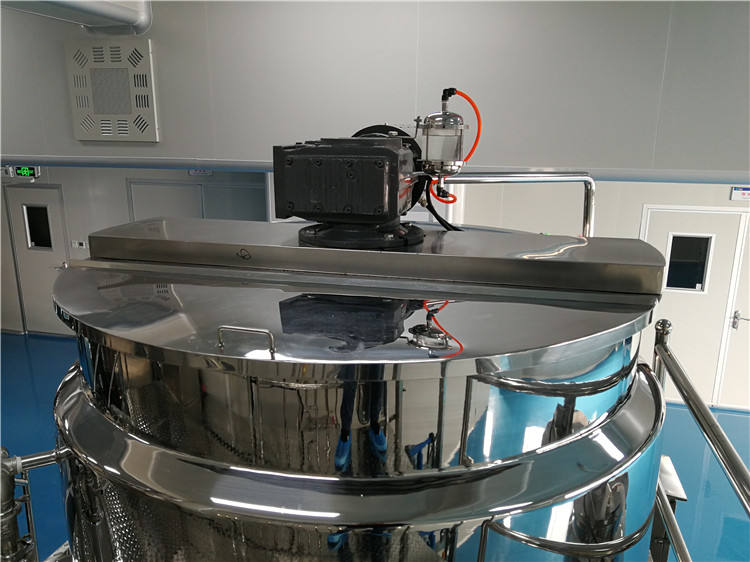

Dabool

Walxaha birta ah, daboolka kala badh furan.

Dhuumaha: Dhammaan qaybaha isku xirka waxay u hoggaansamaan heerarka nadaafadda GMP SUS316L, Qalabka fasalka fayadhowrka iyo valves ayaa la isticmaalaa.

Nidaamka xakamaynta korantada

(waxaa lagu beddeli karaa PLC+ Touch screen)

Daab xoqan iyo suufka kicinta

- Naaxinta buuxda ee 304 birta aan fiicnayn

- Adkeysiga iyo xirashada caabbinta

- fududahay in la nadiifiyo

Homogenizer

- Homogenizer for Bottom (waxaa lagu beddeli karaa in homogenizer sare)

- SUS316L waa walxaha.

- Awoodda baabuurka waxaa lagu go'aamiyaa awoodda.

- Inverter DELTA, xawaaraha kala duwan: 0-3600rpm

- Hababka habaynta: Ka hor inta aan la isku keenin, rotor-ka iyo stator-ka waxaa lagu dhammeeyaa mishiin-goynta siligga oo la safeeyey.

Ikhtiyaari

Madal ayaa sidoo kale ku dari karta dheriga isku dhafka ah. Goobta, golaha xakamaynta ayaa la hirgeliyaa. Kuleyliyaha, isku dhafka xakamaynta xawaaraha, iyo wakhtiga kuleylka ayaa dhamaantood lagu dhammeeyaa nidaamka hawlgalka oo dhamaystiran kaas oo ah qaab-dhismeedka hawl-qabad hufan.

Waxaad isticmaali kartaa noocyo badan oo kala duwan sida aad rabto.

Qalabka waxaa lagu kululeeyaa ama lagu qaboojiyaa kuleyliyaha jaakada, iyadoo ku xiran shuruudaha habka wax soo saarka. Deji heerkul gaar ah, marka heerkulku gaaro heerka loo baahan yahay, qalabka kuleyliyaha ayaa si toos ah u dami doona.

Isku-darka dareeraha ah ee leh cabbirka cadaadiska ayaa loo soo jeedinayaa walxaha viscous.

Raridda & Baakadaha

Kooxda ugu sareysa

Booqashada macmiilka

Adeegga Goobta Macmiilka

Sannadkii 2017, labadayada injineer ayaa u safray warshadda macmiilka ee Spain si ay u bixiyaan adeegga iibka kadib.

2018, injineero ayaa booqday warshadda macmiilka ee Finland adeegga iibka kadib.

Shahaadooyinka Kooxda Sare

Aqoonta iyo Adeegga

- DAmmaanad laba sano ah, dammaanad qaadka matoorka saddexda sano ah, ADEEGGA NOLOSHA

(Adeegga dammaanadda ayaa la bixin doonaa haddii waxyeelladu aysan ahayn natiijada khaladka aadanaha ama hawlgal aan habboonayn.)

- Ku bixi qaybaha kaabayaasha ah qiimo macquul ah.

- Si joogto ah u cusboonaysii qaabaynta iyo barnaamijka.

- 24 saacadood gudahood, uga jawaab su'aal kasta.