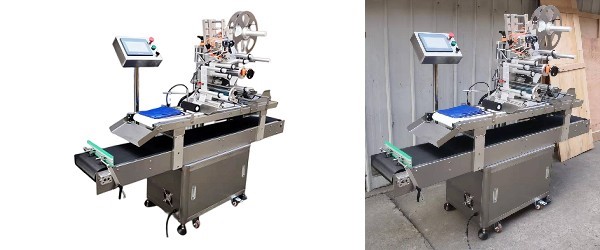

Blog-gani waxa uu ku tusi doonaa codsiyada iyo qaababka ku saabsan mishiinka calaamadaynta fidsan. Aan wax badan ka barano mashiinka calaamadaynta fidsan!

Sharaxaada Alaabta & Codsiyada

Isticmaal:Si toos ah u hel calaamadaynta calaamadda dhejiska ama filimka dhejiska ee dusha siman ama dusha sare ee xagjirka ah ee alaabta.

Summada lagu dabaqi karo:calaamadaha xabagta; filimada xabagta; koodhka kormeerka elegtarooniga ah, bar code iwm.

Alaabta lagu dabaqi karo:Alaabooyinka waa in lagu calaamadiyaa calaamad warqad ama calaamad filim dhinaca sare ah, obliquity hoose, dhinaca qallafsanaanta ama dusha sare ee sanduuqa warqadda, sanduuqa kiiska, dabool dhalada, koob, sanduuqa qurxinta, afargees / dhalada siman, qaybaha korontada, baytariyada iwm.

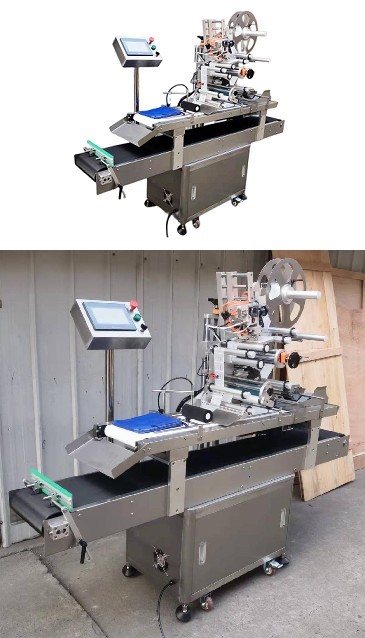

Ikhtiyaarka:1. daabacaadda kulul / mashiinka koodhka 2. Shaqada quudinta tooska ah (sida ku cad badeecada) 3. Shaqada quudinta tooska ah (sida ku cad badeecada) 4. Ku dar booska calaamadaynta 5. Shaqada kale (sida looga baahan yahay macaamilka).

Astaamaha

1.Saamaynta:Naqshadaynta tooska ah waxay hagaajin kartaa hufnaanta calaamadaynta, saxnaanta iyo tayada iyo xasilloonida; Ka fogow dhibaatooyin badan sida hufnaanta hoose ee calaamadinta shaqada, calaamadaynta qallooca, xumbo, laalaab, calaamadin aan joogto ahayn iwm; Qiimaha hoose ee alaabta si wax ku ool ah oo ka dhig sheyga mid aad u qurux badan taas oo u horseedaysa badeecada si aad u tartan badan.

2.Adopt standard PLC+ shaashadda taabashada+ motor stepper+ nidaamka xakamaynta korantada caadiga ah. Isku dhafka badbaadada sare; Isku-xidhka-mashiinka-mashiinka qoraalka Ingiriisiga oo dhammaystiran; wuxuu leeyahay qalad horumarsan oo xasuusiya shaqada iyo shaqada barida; ku habboon in la isticmaalo oo ay fududahay in la ilaaliyo.

3.Naqshad xariif ahTaas oo u oggolaanaysa isticmaaleha in uu si farsamaysan u hagaajiyo qaar ka mid ah qaab-dhismeedka isku-dhafka ah iyo calaamadaynta dabaylaha, waxa ay sahlaysaa in si xor ah loo hagaajiyo booska calaamadaynta (si fudud ayaa loo hagaajin karaa ka dib hagaajinta). Dhammaan kuwan ayaa isbeddelka badeecadaha kala duwan iyo dabaylaha calaamaduhu ka dhigaan kuwo fudud oo waqti badbaadiya.

4.Adopt hagaha badeecada qaabdhismeedka baabi'inta farqigaoo calaamadee qaab-dhismeedka ka-hortagga leexinta. Saxnaanta goobta calaamadaynta waxay gaadhay ± 1mm;

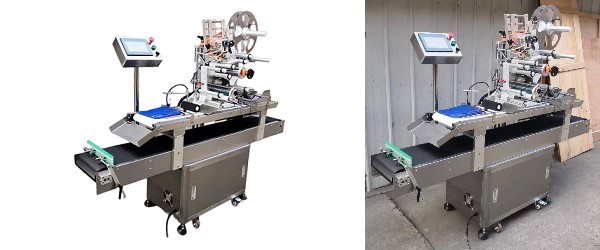

5.Waxay leedahay shaqo ogaansho toos ahsi loo joojiyo calaamadaynta haddii aanay jirin dhalo iyo shaqo toos ah oo toos ah haddii aanay jirin calaamad. Waxay xallisaa dhibaatada calaamadaynta seegga ee ay keentay duubista summada.

6.Wuxuu leeyahay shaqada digniinta khaladka, Shaqada tirinta wax soo saarka, shaqada badbaadinta tamarta (mashiinku wuxuu ku jiri doonaa qaabka heeganka ah marka aysan jirin calaamad calaamad ah wakhti cayiman), iyo qadarka wax-soo-saarka xusuusinta shaqada; Shaqada ilaalinta Parameter-set.

Halbeegyada

| Sumadeynta saxda ah | ± 1mm (ka reeb badeecada iyo weecashada summada) |

| Xawaaraha calaamadaynta | 600-1200BPH (la xiriira cabbirka alaabta) |

| Cabbirka badeecada lagu dabaqi karo | 15≤ ballac≤200mm, dherer≥10mm |

| Cabbirka summada ayaa lagu dabaqi karaa | 15≤ ballac≤130mm, dherer≥10mm |

| Cabbirka mashiinka oo dhan | 1600×800×1400mm (dhererka × ballac× dhererka) |

| Korontada | 110/220V 50/60HZ |

| Miisaanka | 180kg |

Waqtiga post: Seb-27-2022