Video

Buuxiyaha sare ee baakadaha auger

Kooxda sare ee Shanghai waa soo saaraha mishiinada baakadaha buuxinta. Waxaan leenahay awood wax soo saar wanaagsan iyo sidoo kale tignoolajiyada horumarsan ee buuxinta budada auger. Waxaan leenahay servo auger muuqaalka patent.

Intaa waxaa dheer, celceliska wakhtiga wax soo saarka waa 7 maalmood oo keliya naqshadeynta caadiga ah.

Intaa waxaa dheer, waxaan awood u leenahay inaan u habeyno buuxinta auger si waafaqsan shuruudahaaga. Waxaan soo saari karnaa buuxinta auger iyadoo ku saleysan sawirka naqshadeyntaada iyo astaantaada ama macluumaadka shirkadda ee ku qoran calaamadda mashiinka. Waxaan sidoo kale bixin karnaa qaybo buuxinta auger. Haddii aad leedahay qaabeynta shayga, waxaan sidoo kale isticmaali karnaa astaanta gaarka ah.

Farsamada muhiimka ah ee buuxinta servo auger

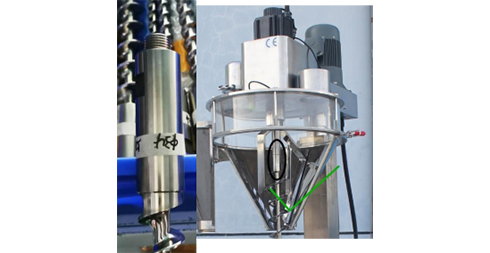

■ Matoorka Servo: Waxaan u isticmaalnaa sumadda Taiwan Delta servo motor si loo xakameeyo auger-ga, si aan u gaarno saxnaanta sare ee buuxinta miisaanka. Calaamadda waa la magacaabi karaa.

servomotor-ku waa firfircoone wareeg ama toosan oo u oggolaanaya in si sax ah loo xakameeyo xagal ama booska toosan, xawaaraha iyo dardargelinta. Waxay ka kooban tahay matoor ku habboon oo lagu daray dareeme loogu talagalay jawaab celinta booska. Waxa kale oo ay u baahan tahay kontaroole aad u casrisan, badiyaa module go'an oo si gaar ah loogu isticmaalo servomotors.

■ Qaybaha dhexe: Qaybaha dhexe ee auger waa qaybta ugu muhiimsan ee buuxinta auger.

Waxaan qabanaa shaqo wanaagsan qaybaha dhexe, habaynta saxnaanta iyo isu-ururinta. Saxnaanta hab-socodka iyo isu-ururinta waa kuwo aan la arki karin isha qaawan oo aan la barbar dhigi karin si macquul ah, laakiin waxay soo muuqan doontaa inta lagu jiro isticmaalka.

■ Xoog saarista sare: Saxnimadu ma sarreyn doonto haddi aysan jirin xooga sare oo ku saabsan goynta iyo usha.

Waxaan isticmaalnaa usheeda dhexe ee caanka ah ee adduunka ee u dhaxaysa auger iyo servo motor.

■ Matoorka Servo: Waxaan u isticmaalnaa sumadda Taiwan Delta servo motor si loo xakameeyo auger-ga, si aan u gaarno saxnaanta sare ee buuxinta miisaanka. Calaamadda waa la magacaabi karaa.

servomotor-ku waa firfircoone wareeg ama toosan oo u oggolaanaya in si sax ah loo xakameeyo xagal ama booska toosan, xawaaraha iyo dardargelinta. Waxay ka kooban tahay matoor ku habboon oo lagu daray dareeme loogu talagalay jawaab celinta booska. Waxa kale oo ay u baahan tahay kontaroole aad u casrisan, badiyaa module go'an oo si gaar ah loogu isticmaalo servomotors.

■ Qaybaha dhexe: Qaybaha dhexe ee auger waa qaybta ugu muhiimsan ee buuxinta auger.

Waxaan qabanaa shaqo wanaagsan qaybaha dhexe, habaynta saxnaanta iyo isu-ururinta. Saxnaanta hab-socodka iyo isu-ururinta waa kuwo aan la arki karin isha qaawan oo aan la barbar dhigi karin si macquul ah, laakiin waxay soo muuqan doontaa inta lagu jiro isticmaalka.

■ Makiinada saxda ah: Waxaan isticmaalnaa mashiinka wax lagu shubo si aan u shiilano xajmi yar, taas oo ka dhigaysa auger in uu leeyahay masaafo isku mid ah iyo qaab aad u sax ah.

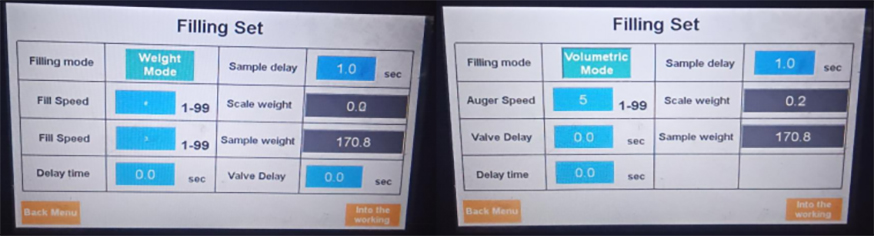

■ Laba qaab oo buuxin ah: Waxa loo kala beddeli karaa qaabka miisaanka iyo qaabka mugga.

Habka codka:

Mugga budada ah ee uu hoos u dhigay sharoobada rogashada hal wareeg ayaa go'an. Koontarooluhu wuxuu xisaabin doonaa inta wareeg ee uu furku u leexdo si uu u gaadho miisaanka buuxinta bartilmaameedka.

Qaabka miisaanka:

Waxa jira unug rar ah oo ku hoos jira saxanka buuxinta si loo cabbiro buuxinta miisaanka wakhtigeeda.

Buuxinta koowaad waa mid degdeg ah oo buuxinta tirada badan si loo helo 80% miisaanka buuxinta bartilmaameedka.

Buuxinta labaad waa mid gaabis ah oo sax ah si loo kabo inta soo hartay 20% iyadoo loo eegayo culeyska waqtiga ku habboon.

qiimaha mashiinka buuxinta auger

Riix halkan si aad u hesho qiimaha buuxinta auger ama buuxinta iibka

Nooca mashiinka buuxinta Auger

Buuxiyaha Auger-ka Semi-atomaatiga ah

Buuxiyaha auger semi-otomaatigga ah wuxuu ku habboon yahay buuxinta xawaaraha hoose. Sababtoo ah waxay u baahan tahay hawlwadeenku inuu saxan ku dhejiyo buuxinta oo uu ka guuro dhalooyinka ka dib marka uu gacanta ku buuxiyo. Waxay xamili kartaa baakidhka dhalada iyo kiishka labadaba. Hoopper-ku wuxuu leeyahay ikhtiyaar bir ah oo buuxa. Dareemaha ayaa la dooran karaa inta u dhaxaysa hagaajinta dareeraha fargeetada iyo dareeraha sawir-qaadista. Waxaad naga heli kartaa buuxinta auger yar iyo moodal caadi ah iyo sidoo kale moodal heer sare ah oo buuxinta budada ah.

| Qaabka | TP-PF-A10 | TP-PF-A11 | TP-PF-A14 |

| Nidaamka xakamaynta | PLC & Shaashada taabashada | PLC & Shaashada taabashada | PLC & Shaashada taabashada |

| Hopper | 11L | 25L | 50L |

| Culayska Xidhmada | 1-50g | 1 - 500 g | 10 - 5000 g |

| Qaadashada miisaanka | By auger | By auger | By auger |

| Jawaab celinta Miisaanka | Miisaanka khadka ka baxsan (sawirka) | Miisaanka khadka ka baxsan (sawirka) | Miisaanka khadka ka baxsan (sawirka) |

| Xaqiijinta Xirmada | ≤ 100g, ≤±2% | ≤ 100g, ≤±2%; 100 - 500g, ≤± 1% | ≤ 100g, ≤±2%; 100 - 500g, ≤± 1%; ≥500g,≤±0.5% |

| Xawaaraha Buuxinta | 40 - 120 jeer min | 40 - 120 jeer min | 40 - 120 jeer min |

| Bixinta Korontada | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Wadarta Awoodda | 0.84 KW | 0.93 KW | 1.4 KW |

| Wadarta Miisaanka | 90kg | 160kg | 260kg |

| Guud ahaan Cabbirrada | 590×560×1070mm | 800×790×1900mm | 1140×970×2200mm |

Semi-otomaatig ahAuger Filleroo leh boorso Clamp

Tani semi-automatic ahbuuxbuuxiyeoo leh shandad isku dhejis ah ayaa ku habboon buuxinta boorsada. Isku-xidhka shandadu wuxuu si toos ah u hayn doonaa bacda ka dib marka uu ku shaabadeeyo saxanka baabuurka. Waxay si toos ah u furmi doontaa bacda buuxinta ka dib. TP-PF-B12 waxay leedahay saxan si kor loogu qaado loona dhaco bacda inta lagu jiro buuxinta si loo yareeyo qaladka boodhka iyo miisaanka sababtoo ah waa qaabka weyn. Marka budada laga soo bilaabo dhamaadka buuxinta ilaa gunta bacda, cufisjiidadu waxay horseedi doontaa qalad sababtoo ah waxaa jira unug rar ah oo ogaanaya miisaanka wakhtiga dhabta ah. Saxanku waxa uu kor u qaadaa bac si ay tuubada buuxintu ugu dhegto bacda. Saxankuna si tartiib ah ayuu u dhacaa marka la buuxinayo.

| Qaabka | TP-PF-A11S | TP-PF-A14S | TP-PF-B12 |

| Nidaamka xakamaynta | PLC & Shaashada taabashada | PLC & Shaashada taabashada | PLC & Shaashada taabashada |

| Hopper | 25L | 50L | 100L |

| Culayska Xidhmada | 1 - 500 g | 10 - 5000 g | 1kg - 50kg |

| Qaadashada miisaanka | By unugga rarka | By unugga rarka | By unugga rarka |

| Jawaab celinta Miisaanka | Jawaab celinta miisaanka onlaynka ah | Jawaab celinta miisaanka onlaynka ah | Jawaab celinta miisaanka onlaynka ah |

| Xaqiijinta Xirmada | ≤ 100g, ≤±2%; 100 - 500g, ≤± 1% | ≤ 100g, ≤±2%; 100 - 500g, ≤± 1%; ≥500g,≤±0.5% | 1 - 20kg, ≤±0.1-0.2%,>20kg, ≤±0.05-0.1% |

| Xawaaraha Buuxinta | 40 - 120 jeer min | 40 - 120 jeer min | 2-25 jeer min |

| Bixinta Korontada | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Wadarta Awoodda | 0.93 KW | 1.4 KW | 3.2 KW |

| Wadarta Miisaanka | 160kg | 260kg | 500kg |

| Guud ahaan Cabbirrada | 800×790×1900mm | 1140×970×2200mm | 1130×950×2800mm |

Nooca khadka tooska ahAuger FillerDhalooyinka

Nooca khadka tooska ahbuuxbuuxiyewaxay khusaysaa buuxinta dhalada budada ah. Waxaa lagu xidhi karaa quudiyaha budada, qasiyaha budada, mashiinka daboolka iyo mishiinka calaamadaynta si loo sameeyo khad baakad toos ah. Gaadhi-qaaduhu waxa uu soo geliyaa dhalooyin, baakinta dhaladu waxa ay dib u haysaa dhalooyinka si uu dhalo haye u kor u qaado dhalada buuxinta hoosteeda. Gaadhi-qaaduhu waxa uu hore u dhaqaajiyaa dhalooyinka ka dib marka uu si toos ah u buuxiyo. Waxay ku xamili kartaa dhalada cabbirrada kala duwan ee hal mashiin waxayna ku habboon tahay isticmaale leh in ka badan hal baakado.

Joojinta birta aan fiicnayn iyo birta si buuxda u daboolan waa ikhtiyaari. Waxaa jira laba nooc oo dareemaha la heli karo. Waxaana lagu habeyn karaa in lagu daro shaqada miisaanka onlaynka ah si loo gaaro saxnimo aad u sareysa.

| Qaabka | TP-PF-A21 | TP-PF-A22 |

| Nidaamka xakamaynta | PLC & Shaashada taabashada | PLC & Shaashada taabashada |

| Hopper | 25L | 50L |

| Culayska Xidhmada | 1 - 500 g | 10 - 5000 g |

| Qaadashada miisaanka | By auger | By auger |

| Jawaab celinta Miisaanka | ≤ 100g, ≤±2%; 100 - 500g, ≤± 1% | ≤ 100g, ≤±2%; 100 - 500g, ≤± 1%; ≥500g,≤±0.5% |

| Xaqiijinta Xirmada | 40 - 120 jeer min | 40 - 120 jeer min |

| Xawaaraha Buuxinta | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Wadarta Awoodda | 1.2 KW | 1.6 KW |

| Wadarta Miisaanka | 160kg | 300kg |

| Guud ahaan Cabbirrada | 1500×760×1850mm | 2000×970×2300mm |

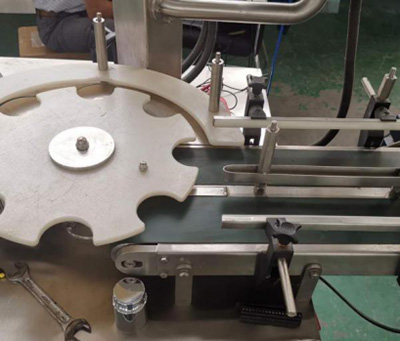

Rotari Toos ahAuger Filler

Rotarybuuxbuuxiyewaxaa loo isticmaalaa in lagu buuxiyo budada dhalooyinka leh xawaare sare. Buuxiyaha noocaan ah wuxuu ku habboon yahay macmiilka leh hal ama laba dhalo oo dhexroor ah sababtoo ah shaagagga dhaladu wuxuu xamili karaa dhexroor kaliya. Si kastaba ha ahaatee, saxnaanta iyo xawaaruhu way ka fiican yihiin nooca xariiqda buuxinta. Waxaa intaa dheer, nooca rotary wuxuu leeyahay shaqada miisaanka onlaynka ah iyo diidmada. Buuxiyaha ayaa buuxin doona budada marka loo eego culeyska waqtiga dhabta ah ee buuxinta, iyo shaqada diidmada ayaa ogaan doonta oo ka takhalusi doonta miisaanka aan u qalmin.

Daboolka mashiinka waa ikhtiyaari.

| Qaabka | TP-PF-A31 | TP-PF-A32 |

| Nidaamka xakamaynta | PLC & Shaashada taabashada | PLC & Shaashada taabashada |

| Hopper | 35L | 50L |

| Culayska Xidhmada | 1-500g | 10 - 5000 g |

| Qaadashada miisaanka | By auger | By auger |

| Cabbirka weelka | Φ20 ~ 100mm, H15 ~ 150mm | Φ30 ~ 160mm, H50 ~ 260mm |

| Xaqiijinta Xirmada | ≤ 100g, ≤±2% 100 - 500g, ≤±1% | ≤ 100g, ≤±2%; 100-500g, ≤±1% ≥500g,≤±0.5% |

| Xawaaraha Buuxinta | 20 - 50 jeer min | 20 - 40 jeer min |

| Bixinta Korontada | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Wadarta Awoodda | 1.8 KW | 2.3 KW |

| Wadarta Miisaanka | 250kg | 350kg |

| Guud ahaan Cabbirrada | 1400*830*2080mm | 1840×1070×2420mm |

Buuxiyaha labajibbaaran ee madaxa budada ah

Buuxiyaha labajibbaaran ee madaxa auger wuxuu ku habboon yahay buuxinta xawaaraha sare. Xawaaraha ugu badan oo gaadha 100bpm. Hubinta miisaanka iyo nidaamka diidmada ayaa ka hortagaya luminta alaabta qaaliga ah sababtoo ah xakamaynta saxnaanta sare ee miisaanka. Waxaa si weyn loogu isticmaalaa khadka soo saarista budada caanaha.

| Habka qaadashada | Buuxinta labajibbaaran ee buuxinta buuxinta oo leh miisaan online ah |

| Buuxinta Miisaanka | 100 - 2000 g |

| Cabbirka weelka | Φ60-135mm; H 60-260mm |

| Buuxinta Saxnaanta | 100-500g, ≤±1g; ≥500g,≤±2g |

| Xawaaraha Buuxinta | In ka badan 100 qasac/daqiiqo (#502),In ka badan 120 qasac/daqiiqo (#300 ~ #401) |

| Bixinta Korontada | 3P AC208-415V 50/60Hz |

| Wadarta Awoodda | 5.1 kw |

| Wadarta Miisaanka | 650kg |

| Bixinta hawada | 6kg/cm 0.3cbm/min |

| Guud ahaan cabbirka | 2920x1400x2330mm |

| Mugga Hopper | 85L (ugu weyn) 45L (caawin) |

Nidaamka Baakadaha budada

Marka buuxinta auger-ku uu ku shaqeeyo mashiinka wax lagu xidho, waxa ay samaysaa mishiinka baakadaha budada ah. Waxaa lagu xidhi karaa shandad filim duuban oo buuxinta iyo mashiinka wax lagu xidho, ama mashiinka wax lagu xidho ee yar yar iyo mishiinka baakadaha rotary ama kiish hore loo sameeyay.

Astaamaha buuxinta Auger

■ U rog roga si aad u hubiso saxnaanta sare ee buuxinta.

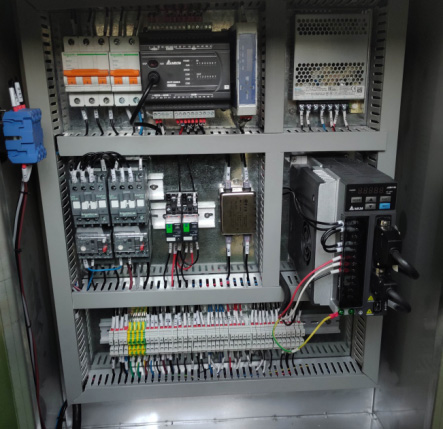

■ Koontaroolka PLC oo leh muraayadda taabashada, oo ay fududahay in la shaqeeyo.

■ Matoorka servo-ga waxa uu wadaa auger si uu u hubiyo waxqabad xasiloon.

■ Si dhakhso leh u gooya hopper waa nadiifin fudud iyada oo aan qalab lahayn.

■ Mashiinka oo dhan waa bir aan 304 ah.

■ Shaqada miisaanka onlaynka ah iyo saamiga la socodka walxaha waxay ka gudbaan dhibka culeyska buuxinta ee ay sababtay isbeddelka cufnaanta alaabta.

■ Ku hayso barnaamijka 20 qaybood oo cunto karin ah si hadhow loo isticmaalo.

■ Beddelida auger si loogu xidho badeecooyin kala duwan oo miisaanyo kala duwan leh, laga bilaabo budo khafiif ah ilaa qaybo.

■ Iyadoo shaqada diidmada miisaanka aan tayada lahayn.

■ Isku xirka luqadaha badan

Liiska isku xidhka . A,

| Maya | Magaca | Pro. | Summada |

| 1 | PLC | Taiwan | DELTA |

| 2 | Shaashada taabashada | Taiwan | DELTA |

| 3 | Servo motor | Taiwan | DELTA |

| 4 | Servo darawalka | Taiwan | DELTA |

| 5 | Beddelida budada |

| Schneider |

| 6 | Gurmadka degdega ah |

| Schneider |

| 7 | Xiriiriyaha |

| Schneider |

| 8 | Gudbinta |

| omron |

| 9 | Bedelka u dhowaanshaha | Kuuriya | Autonics |

| 10 | Dareemaha heerka | Kuuriya | Autonics |

B: Agabka

| Maya | Magaca | Tirada | Odhaah |

| 1 | Fuse | 10pcs |  |

| 2 | Jiggle beddelka | 1pcs | |

| 3 | 1000 g oo casiir ah | 1pcs | |

| 4 | Socket | 1pcs | |

| 5 | Badaloolka | 1pcs | |

| 6 | Xidhiidhiyaha fur | 3pcs |

C: Sanduuqa Qalabka

| Maya | Magaca | Tirada | Odhaah |

| 1 | Spanner | 2pcs |

|

| 2 | Spanner | 1set | |

| 3 | Kaashawiito Slotted | 2pcs | |

| 4 | Kaashawiito Phillips | 2pcs | |

| 5 | Buugga isticmaale | 1pcs | |

| 6 | Liiska baakad | 1pcs |

Faahfaahinta buuxinta Auger

1. Hopper Ikhtiyaar ah

Hopper badh furan

Heerkan kala qaybsanaantu waa

fududahay in la furo oo la nadiifiyo.

Hopper ka laadlaadsan

Hopper-ka la isku daray wuxuu ku habboon yahay budo aad u fiican sababtoo ah ma jirto wax farqi ah oo ku yaal qaybta hoose ee hopper

2. Habka buuxinta

Waxaa loo dhex mari karaa qaabka miisaanka iyo qaabka mugga.

Habka codka

Mugga budada ah ee uu hoos u dhigay sharoobada rogashada hal wareeg ayaa go'an. Koontarooluhu wuxuu xisaabin doonaa inta wareeg ee uu furku u leexdo si uu u gaadho miisaanka buuxinta bartilmaameedka.

Qaabka miisaanka

Waxa jira unug rar ah oo ku hoos jira saxanka buuxinta si loo cabbiro buuxinta miisaanka wakhtigeeda.

Buuxinta koowaad waa mid degdeg ah oo buuxinta tirada badan si loo helo 80% miisaanka buuxinta bartilmaameedka.

Buuxinta labaad waa mid gaabis ah oo sax ah si loo kabo inta soo hartay 20% iyadoo loo eegayo culeyska waqtiga ku habboon.

Habka miisaanka ayaa leh saxnaan sare laakiin xawaare hoose.

Buuxiyeyaasha Auger ee alaab-qeybiyeyaasha kale hal qaab oo kaliya: qaabka mugga

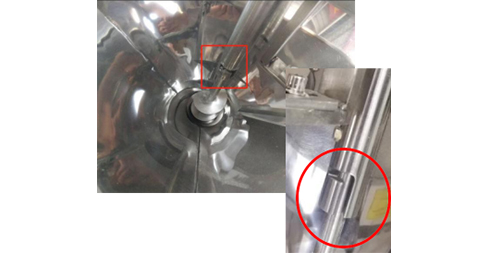

3. Habka hagaajinta Auger

Kooxda ugu Sarreysa ee Shanghai: Nooca birta

Ma jirto meel bannaan oo loogu talagalay

budo lagu qariyo gudaha,

oo ay fududahay in la nadiifiyo

Alaab-qeybiyeyaal kale: Nooca Hang

Waxaa jiri doona budo ku qarinaysa gudaha qaybta isku xirka, taas oo ay adag tahay in la nadiifiyo, oo xumaan doonta xataa budo cusub oo wasakh ah.

4. Gacmaha gacanta

Kooxda ugu sareysa Shanghai

Alaab-qeybiye kale

Waxay ku habboon tahay buuxinta dhalooyinka / bacaha dhererkoodu kala duwan yahay. U rog giraangiraha gacanta si aad u kacdo oo hoos ugu dhigto buuxinta. Oo ciddayadu waa ka dhumuc weyn tahay oo ka xoog badan tahay kuwa kale.

5. Habaynta

Kooxda ugu sareysa Shanghai

alxanka buuxa, oo ay ku jiraan cidhifka hopper.

Fudud in la nadiifiyo

6. Saldhigga matoorka

7. Hawada ka soo baxda

Mashiinka oo dhan wuxuu ka samaysan yahay SS304 oo ay ku jiraan saldhigga iyo haystaha matoorka, kaas oo ka xoog badan oo heerkiisu sarreeyo.

Haysta matoorku maaha SS304.

8. Laba marin oo wax soo saar

Dhalooyinka leh buuxinta tayada leh

miisaanku wuxuu maraa hal marin

Dhalooyinka leh buuxinta aan u qalmin

miisaanka si toos ah ayaa loo diidi doonaa

marinka kale ee suunka.

9. Cabirrada kala duwan ee cabbiraadda auger iyo buuxinta nozzles

Mabda'a buuxinta auger waa in mugga budada uu hoos u dhigay auger roga hal goobaabin uu go'an yahay. Markaa cabbirro kala duwan oo auger ah ayaa loo isticmaali karaa noocyo kala duwan oo miisaan buuxin ah si loo gaadho saxsanaan sare oo waqti badan loo badbaadiyo.

Waxaa jira tuubo cabbirka cabbirka u dhiganta ee cabbir kasta.

tusaale ahaan, dia. 38mm fur ayaa ku habboon buuxinta 100g-250

Waxyaabaha soo socdaa waa cabbirrada auger iyo miisaanka buuxinta la xidhiidha

Cabbirka Koobka iyo Xadka Buuxinta

| Dalbo | Koob | Dhexroorka Gudaha | Dhexroorka dibadda | Buuxinta Range |

| 1 | 8# | 8 | 12 | |

| 2 | 13 # | 13 | 17 | |

| 3 | 19 # | 19 | 23 | 5-20g |

| 4 | 24# | 24 | 28 | 10-40g |

| 5 | 28# | 28 | 32 | 25-70g |

| 6 | 34# | 34 | 38 | 50-120g |

| 7 | 38# | 38 | 42 | 100-250g |

| 8 | 41 # | 41 | 45 | 230-350g |

| 9 | 47# | 47 | 51 | 330-550g |

| 10 | 53# | 53 | 57 | 500-800g |

| 11 | 59# | 59 | 65 | 700-1100g |

| 12 | 64# | 64 | 70 | 1000-1500g |

| 13 | 70# | 70 | 76 | 1500-2500g |

| 14 | 77# | 77 | 83 | 2500-3500g |

| 15 | 83# | 83 | 89 | 3500-5000g |

Haddii aadan hubin cabbirkaaga ku habboon, fadlan nala soo xiriir waxaanan kuu dooran doonnaa cabbirka cabbirka ugu habboon ee kuugu habboon.

Bandhig warshadeedka Auger buuxinta

Habaynta Auger buuxinta

Naqshad Kaalmayn Kombiyuutar

shiidid

qodis

Soo jeestay

foorarsanaan

alxanka

shaandhaynta

buffing

xakamaynta korantada

■ Wax yar oo Dufan ah ku darso silsiladda mootooyinka hal mar saddexdii ama afartii biloodba.

■ Xarigga labada dhinac ee hopper ayaa gaboobay ku dhawaad hal sano ka dib. Ku beddel haddii loo baahdo.

■ Nadiifi hopper wakhtiga.