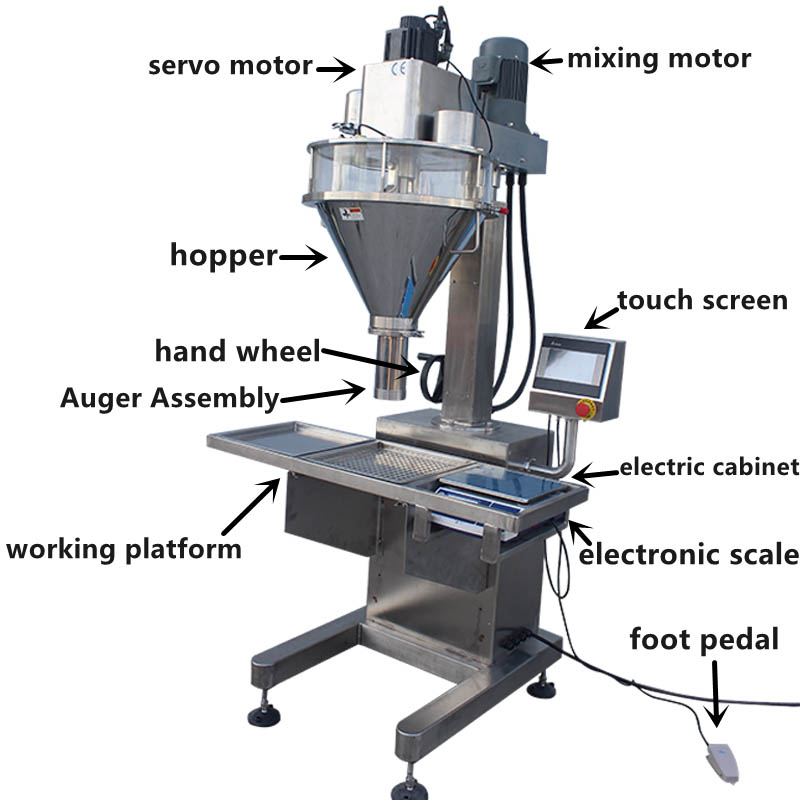

Buuxiyaha budada ah ee nus toos ah

Sawir jabinta budada buuxinta

Ka kooban

1. Servo motor

2. Matoorka isku dhafan

3. Hopper

4. Taayir-gacmeed

5. shirka Auger

6. Shaashada taabashada

7. Goobta shaqada

8. Golaha korontada

9. Miisaanka elegtarooniga ah

10. Baadida cagta

Mabda'a hawlgalka

Sidee buu u shaqeeyaa budada buuxinta?

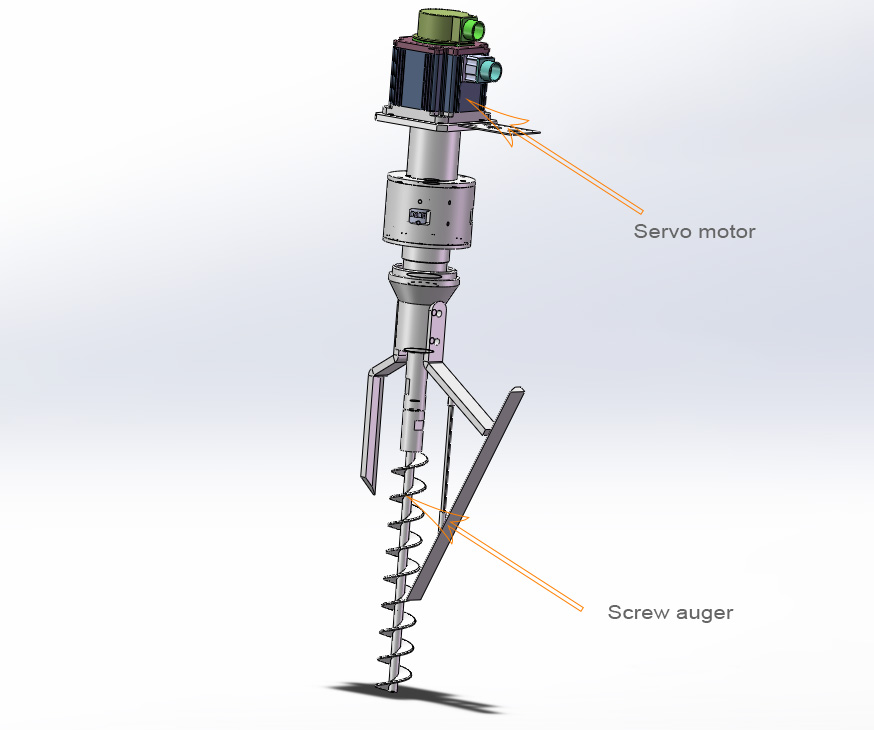

Matoorka Servo wuxuu si toos ah u wadaa furaha cabbiraadda, wareegga mashiinka servo si uu u xakameeyo wareegtada cabbirka cabbirka. Wareegga cabbirka cabbirka ayaa qaadi doona socodka badeecada, alaabtu waxay buuxin doontaa dhammaan farqiga u dhexeeya furaha. Wareegga mitirku wuxuu wareegaa hal wareeg, PLC waxay u rogi doontaa hal wareeg oo garaaca wadnaha go'an, iyo kontaroolaha barnaamijka PLC iyadoo loo eegayo qiimaha miisaanka loo dejiyay, marka loo eego cufnaanta si loo xisaabiyo mugga u dhigma, ka dib xisaabinta calaamadda garaaca garaaca wadnaha ee u dhiganta darawalka servo, ka dibna darawalka servo sida ku cad calaamadda gelitaanka PLC si loo wado tirada servo ee u dhiganta wareegga wareegga.

■ Qalab weelka wax lagu dhaqo si loo dammaanad qaado saxnaanta buuxinta.

■ Delta summada PLC xakamaynta iyo soo bandhigida shaashadda taabashada.

■ Matoorka Servo wuxuu wadaa furaha si uu u dammaanad qaado waxqabadka xasilloon.

■ Kala qaybsanaanta nooca hopper si fudud u furan oo xidhitaan la'aan, si fudud ayaa loo dhaqi karaa oo si habboon u beddeli kara alaabada kala duwan ee kala duwan ee budada ganaaxa ilaa granule iyo miisaan kala duwan ayaa la soo rogi karaa.

■ Jawaab celinta miisaanka iyo saamiga agabka, taas oo ka gudubta dhibaatooyinka buuxinta isbeddelka miisaanka sababtoo ah isbeddelka cufnaanta alaabta.

■ Ku keydi 10 nooc oo caano ah shaashadda taabashada.

■ Isku xirka luqadda Shiinaha/Ingiriisi.

■ Qalab aan la saari karin qaybaha beddelka.

Sharaxaada

Buuxiyaha budada Auger wuxuu qaban karaa qiyaas iyo shaqo buuxin. Waa mashiinka buuxinta mugga. Inta badan waxa uu ka kooban yahay martigeliyaha qiyaasaha, sanduuqa qaybinta korontada, golaha kontoroolka iyo miisaanka elegtarooniga ah. Sababtoo ah naqshadeynta asalka ah ee asalka ah, mashiinku wuxuu labadaba ku habboon yahay baakadaha budada qulqulka leh iyo sheyga granular illiquid, oo ay ku jiraan budada caanaha, monosodium glutamate, cabitaan adag, sonkor, dextrose, qaxwaha, calafka, daawada adag, sunta cayayaanka, lagu daro budada granular, midabada, iwm. Intaa waxaa dheer, iyadoo ay ugu wacan tahay isticmaalka qaaska ah ee khaaska ah ee filler-waqtiga dhabta ah iyo kombuyuutarku waa mid aad u sarreeya. Waxaa loo isticmaali karaa codsiyo kali ah ama waxaa lagu dhex dari karaa khadadka gudbinta tooska ah iyo mashiinnada boorsooyinka.

Taxanaha TP Mashiinka buuxinta budada wuxuu leeyahay noocyo kala duwan: hal nus-otomaatig ah iyo moodooyin toos ah, laba-geesood oo isku-dhafan iyo moodooyin toos ah, iwm, si ay ula qabsadaan shuruudaha wax soo saarka ee kala duwan. (Qalabka gaarka ah, shirkadeena waxay keeni kartaa qalab gaar ah.)

Faahfaahin

1. Matoorka Servo: servo motor si toos ah u wado cabbiraadda cabbirka, si loo dammaanad qaado saxnaanta buuxinta.

2. Matoorka isku dhafka ah: Isku-darka qalabka isku-dhafka mootada iyadoo la adeegsanayo silsilado iyo sprockets isku xira, qalabka isku-dhafka ah ee gudaha gudaha hopper, si loo hubiyo walxaha heerka isku midka ah ee hopper, markaa dammaanad qaado saxnaanta buuxinta.

3. Meesha hawada laga soo saaro: SS sheyga hawo-mareenka ah, marka alaabta lagu shubo hopper, hawada ku jirta hopper ayaa u baahan in laga saaro, daloolka hawadu wuxuu leeyahay filter si looga fogaado boodhka budada ah ee ka soo baxa hopper.

4. Meesha Quudinta: godku waxa uu ku xidhi karaa dareeraha mishiinada quudinta, sida dareeraha wareejinta isbiirtada, dareeraha vacuum feeder ee si toos ah u rarida ama maqaarka hoonka iyo rarka gacanta.

5. Dareemka Heerka: Dareemkan ayaa dareemi doona heerka shay ee hopper buuxinta, oo u diri doona calaamad si uu u ogolaado in mashiinka quudinta uu si toos ah u soo galo.

6. Shaashadda taabashada Delta: deji miisaanka buuxinta, xawaaraha iyo cabbirrada kale sida waafaqsan shuruudaha buuxinta.

7. Kursiga shaqada iyo ururiyaha qulqulka: ku habboon in weel la dul dhigo fadhiga shaqada si loo buuxiyo, ururiyaha qulqulaya wuxuu ururin karaa walxaha daatay, si loo hubiyo jawiga shaqada ee nadiifka ah.

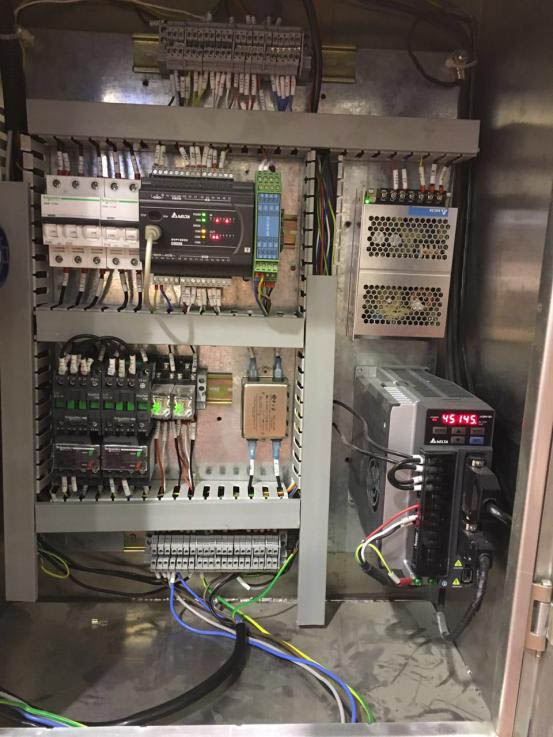

8. Golaha korantada: isticmaal qalabka korantada ee caanka ah, si loo hubiyo xasiloonida mashiinka iyo nolosha adeegga mashiinka.

9. Screw nooca cabbiraadda cabbiraadda: fududahay in la nadiifiyo oo tan ugu muhiimsani ma jirto wax ku qarinaya qaybta ku xiran.

10. Taayir-gacmeed: si fudud loo hagaajiyo dhererka sanbabada buuxinta, oo ku habboon dhalooyinka dhererka ee kala duwan / dhalooyinka / bacaha.

11. Kala qaybsanaanta nooca hopper: Si loo furo oo loo xiro hopper-ka iyada oo aan la isticmaalin, si fudud ayaa loo dhaqi karaa oo loo beddelaa si ku habboon si loogu dabaqo badeecado kala duwan oo kala duwan oo u dhexeeya budo ganaax ilaa granule iyo miisaan kala duwan ayaa la soo rogi karaa

12. Hoopper alxan leh oo buuxa: iyada oo aan lahayn meel bannaan oo lagu qariyo boodhka budada hawada, way fududahay in lagu nadiifiyo biyo ama hawo. Oo aad u qurux badan oo kaydsan.

Halbeegga ugu muhiimsan

| Qaabka | TP-PF-A10 | TP-PF-A11/A11N | TP-PF-A11S/A11NS | TP-PF-A14/A14N | TP-PF-A14S/A14NS |

| Nidaamka xakamaynta | PLC & shaashadda taabashada | PLC & Shaashada taabashada | PLC & Shaashada taabashada | ||

| Hopper | 11L | 25L | 50L | ||

| Baakadwsideed | 1-50g | 1 - 500 g | 10 - 5000 g | ||

| Qaadashada miisaanka | By auger | By auger | By unugga rarka | By auger | By unugga rarka |

| Jawaab celinta Miisaanka | Miisaanka khadka ka baxsan (sawirka) | Miisaanka khadka ka baxsan (sawirka) | Jawaab celinta miisaanka onlaynka ah | Miisaanka khadka ka baxsan (sawirka) | Jawaab celinta miisaanka onlaynka ah |

| Baakadasax | ≤ 100g, ≤±2% | ≤ 100g, ≤±2%; 100-500 g, ≤±1% | ≤ 100g, ≤±2%; 100-500 g, ≤±1%; ≥500g,≤±0.5% | ||

| Xawaaraha Buuxinta | 40-120 jeers/min | 40-120 jeer/min | 40-120 jeer/min | ||

| AwoodSkor u kaca | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | ||

| Wadarta Awoodda | 0.84 KW | 0.93 KW | 1.4 KW | ||

| Wadarta Miisaanka | 90kg | 160kg | 260kg | ||

| Guud ahaan Cabirka | 590×560×1070mm | 800×790×1900mm | 1140×970×2200mm | ||

Astaanta Agabka

| Maya | Magaca | Pro. | Summada |

| 1 | PLC | Taiwan | DELTA |

| 2 | Shaashada taabashada | Taiwan | DELTA |

| 3 | Servo motor | Taiwan | DELTA |

| 4 | Servo darawalka | Taiwan | DELTA |

| 5 | Bedelsahayda budada ah |

| Schneider |

| 6 | Gurmadka degdega ah |

| Schneider |

| 7 | Xiriiriyaha |

| Schneider |

| 8 | Gudbinta |

| omron |

| 9 | U dhowaanshahah | Kuuriya | Autonics |

| 10 | Dareemaha heerka | Kuuriya | Autonics |

Nooc toos ah buuxinta budada qalalan

| Qaabka | TP-PF-A20/A20N | TP-PF-A21/A21N | TP-PF-A22/A22N | TP-PF-301/301N | TP-PF-A302/302N |

| Nidaamka xakamaynta | PLC & Shaashada taabashada | PLC & Shaashada taabashada | PLC & Shaashada taabashada | PLC & Shaashada taabashada | PLC & Shaashada taabashada |

| Hopper | 11L | 25L | 50L | 35L | 50L |

| Culayska Xidhmada | 1-50g | 1 - 500 g | 10 - 5000 g | 1 - 500 g | 10 - 5000 g |

| Qaadashada miisaanka | By auger | By auger | By auger | By unugga rarka | By unugga rarka |

| Xaqiijinta Xirmada | ≤ 100g, ≤±2% | ≤ 100g, ≤±2%; 100-500 g, ≤±1% | ≤ 100g, ≤±2%; 100-500 g, ≤±1%; ≥500g,≤±0.5% | ≤ 100g, ≤±2%; 100 - 500g, ≤± 1%

| ≤ 500g, ≤± 1%;>500g, ≤±0.5%

|

| Xawaaraha Buuxinta | 40-60 dhalooyinkahalkii daqiqo | 40-60 dhalooyinkahalkii daqiqo | 40-60 dhalooyinkahalkii daqiqo |

20-50dhalooyinkahalkii daqiqo

|

20-40 dhalooyinkahalkii daqiqo

|

| Bixinta Korontada | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Wadarta Awoodda | 0.84 KW | 1.2 KW | 1.6 KW | 1.2kw | 2.3kw |

| Wadarta Miisaanka | 90kg | 160kg | 300kg | 260kg | 360kg |

| Guud ahaan Cabirka | 590×560×1070mm | 1500×760×1850mm | 2000×970×2300mm | 1500×760×2050mm

| 2000×970×2150mm

|

Hordhac Guud

Nooca tooska ah ee budada qalalan ayaa leh nooca toosan iyo nooc toos ah oo wareeg ah. Buuxiyaha budada ah ee nooca otomaatiga ah inta badan buuxin dhalada/ gasacadaha/ dhalooyinka, bacuhu si joogto ah uguma taagnaan karaan gaadiidka gudbinta, marka mashiinka buuxinta budada tooska ah kuma habboona buuxinta bacaha. Buuxiyaha budada ah ee nooca tooska ah ee tooska ah, waxay caadi ahaan ku habboon tahay dhalooyinka dhexroorka weyn ee daasadaha/ gasacadaha/ dhalooyinka. Marka la eego dhalooyinka dhexroorka yar yar / qasacadaha / dhalooyinka, nooca rotary si toos ah ayaa aad ugu habboon, sababtoo ah waxay si sax ah u heli kartaa hoosta godka buuxinta ee buuxinta.

Buuxinta laba-buuxiyaha oo leh miisaan online ah

Buuxiyaha budada ah ee taxanaha ah waa mid cusub oo nashqadeeyay kaas oo aanu ka dhignay in aanu hal dhinac gelinayno Quudinta Gadaashii hore. Buuxinta laba-geesoodka ah oo ku dhex jira hal sadar buuxinta caawiye-guud iyo nidaamka quudintu waxay ilaalin kartaa saxnaanta sare waxayna ka saartaa nadiifinta daalka leh ee miiska leexashada. Buuxiyaha budada Auger wuxuu qaban karaa miisaanka saxda ah & shaqada buuxinta, sidoo kale waxaa lagu dari karaa mashiinada kale si loo dhiso khad wax soo saarka oo dhan. Buuxiyaha budada qalalan waxaa loo isticmaali karaa buuxinta budada caanaha, budada albumenka, xashiishka, dextrose, burka bariiska, budada kookaha, cabitaanka adag, iyo wixii la mid ah.

Tilmaamaha ugu muhiimsan

■ Hal xariiq laba-buuxiyeyaasha, Main & Caawin buuxinta si ay shaqada ugu sii jirto si sax ah.

■ Gudbinta can-kor-ka-sare iyo tooska ah waxaa xakameynaya nidaamka servo iyo pneumatic, noqo mid sax ah, xawaare badan.

■ Matoorka Servo iyo darawalka servo ayaa xakameynaya furka, joogso oo sax

■ Qaab dhismeedka birta aan fiicnayn, Kala qaybsan hopper oo leh sifooyin gudaha ah ayaa ka dhigaya in si fudud loo nadiifiyo.

■ PLC & screen touch waxay fududeeyaan in la shaqeeyo.

■ Nidaamka miisaamidda jawaab-celinta degdega ah ayaa ka dhigaysa meesha xoogga badan mid dhab ah

■ Shaadhka gacantu waxa uu ka dhigayaa is-weydaarsiga faylalka kala duwan si fudud.

■ Daboolka ururinta boodhka ayaa la kulma dhuumaha oo ka ilaaliya deegaanka wasakhda.

■ Naqshad toosan oo toosan ayaa mishiinka ka dhiga meel yar

■ Isku-xidhka isku-xidhka isku-xidhka wax-soo-saarka wax wasakh ah kama sameeyo birta

■ Habka: kor u qaadi kara → gariirka → buuxinta → gariirka → gariirka → miisaamidda & baafinta → xoojinta → hubinta miisaanka

■ Iyada oo leh nidaamka dhexe ee kantaroolka oo dhan.

Xogta farsamada ugu weyn

| Habka qaadashada | Buuxinta laba-buuxiyaha oo leh miisaan online ah |

| Buuxinta Miisaanka | 100 - 2000 g |

| Cabbirka weelka | Φ60-135mm; H 60-260mm |

| Buuxinta Saxnaanta | 100-500g, ≤±1g;≥500g,≤±2g |

| Xawaaraha Buuxinta | In ka badan 50 qasac/daqiiqo (#502),In ka badan 60 qasac/daqiiqo (#300 ~ #401)) |

| Bixinta Korontada | 3P AC208-415V 50/60Hz |

| Wadarta Awoodda | 3.4 kw |

| Wadarta Miisaanka | 450kg |

| Bixinta hawada | 6kg/cm 0.2cbm/min |

| Guud ahaan cabbirka | 2650×1040×2300mm |

| Mugga Hopper | 50L (ugu weyn) 25L (caawin) |

Dhig liiska

| Maya | Magaca | Qaabka Tilmaamid | Aagga wax soo saarka, Summada |

| 1 | birta aan-dhalatada lahayn | SUS304 | Shiinaha |

| 2 | PLC | FBs-60MCT2-AC | Taiwan Fatek |

| 3 | HMI | Schneider HMIGXO5502 | Schneider |

| 4 | Buuxinta matoorka servo | TSB13102B-3NTA | TaiwanTECO |

| 5 | Buuxinta darawalka servo | TSTEP30C | TaiwanTECO |

| 6 | Buuxinta matoorka servo | TSB08751C-2NT3 | TaiwanTECO |

| 7 | Buuxinta darawalka servo | TSTEP20C | TaiwanTECO |

| 8 | Servo motor | TSB08751C-2NT3 | TaiwanTECO |

| 9 | Servo darawalka | TSTEP20C | TaiwanTECO |

| 10 | Matoorka kicinta | DRS71S4 | SEW/SEW-EURODRIVE |

| 11 | Matoorka kicinta | DR63M4 | SEW/SEW-EURODRIVE |

| 12 | Gear yareeya | NRV5010 | STL |

| 13 | Waalka Electromagnetic | TaiwanSHAKO | |

| 14 | Silinder | TaiwanAirtac | |

| 15 | Filter-ka hawada iyo xoojinta | AFR-2000 | TaiwanAirtac |

| 16 | matoor | 120W 1300rpmQaabka:90YS120GY38 | TaiwanJSCC |

| 17 | Wax yareeya | Saamiga:1:36,Qaabka:90GK(F)36RC | TaiwanJSCC |

| 18 | Gariir | CH-338-211 | KLSX |

| 19 | Bedel | HZ5BGS | WenzhouCansen |

| 20 | Circuit jabiye | Schneider | |

| 21 | Gurmadka degdega ah | Schneider | |

| 22 | Shaandhaynta EMI | ZYH-EB-10A | BeijingZYH |

| 23 | Xiriiriyaha | CJX2 1210 | WenzhouCHINT |

| 24 | Isku-gudbinta kulaylka | NR2-25 | WenzhouCHINT |

| 25 | Gudbinta | MY2NJ 24DC | JapanCumar |

| 26 | Korontada beddeleysa | ChangzhouChenglian | |

| 27 | AD Module Miisaanka | DAHEBACK | |

| 28 | Loadcell | Mettler-Toledo | |

| 29 | Dareemaha Fiber | RiKO FR-610 | KuuriyaAutonics |

| 30 | Dareemka sawirka | KuuriyaAutonics | |

| 31 | Dareemaha heerka | KuuriyaAutonics |

Liiska agabka

| MAYA | MAGACA | SPECS | CUTUB | LAMBARKA | KA fiirso |

| 1 | SPANNER |

|

QAYB | 2 |

QALABKA |

| 2 | DAAYEERKASPANNER |

|

QAYB | 2 |

QALABKA |

| 3 | HEXAGON RING SPANNER |

|

SET | 1 |

QALABKA |

| 4 | FILIPS DRAARE |

| XIDHIIDH | 2 |

QALABKA |

| 5 | DAREENKA XARAN |

| XIDHIIDH | 2 |

QALABKA |

| 6 | PLUG |

| PIC | 1 | Qalabka |

| 7 | PRESSURIZING DISC |

| PIC | 2 | Qalabka |

| 8 | XANUUNKA | 1000G | PIC | 1 | Qalabka |

| 9 | HOOPS |

| PIC | 2 | Qalabka |

| 10 | Boorka-URURINTA BOOLKA |

| PIC | 2 | Qalabka |

| 11 | SCREW |

| SET | 2 | Qalabka |

| 12 | TILMAANTA ISTICMAALKA |

| NAQIILI | 1 | FAYSO |

Buuxiyaha budada weyn ee boorsada

Qaabkan buuxinta budada qalalan waxaa inta badan loogu talagalay budada weyn ee bacda taas oo si fudud u soo saari karta boodhka iyo baakad sax ah oo loo baahan yahay. Dareemka culeysku wuxuu ka hooseeyaa saxanka, iyadoo lagu saleynayo calaamadda jawaab-celinta ee lagu bixiyo dareenka miisaanka hoose, si loo sameeyo buuxin degdeg ah iyo buuxin tartiib tartiib ah oo ku salaysan miisaanka horay loo dejiyay, si loo dammaanad qaado saxnaanta baakadaha sare, buuxinta budada qalalan waxay samaynaysaa cabbir, laba-buuxinta, iyo shaqada kor-hoos, iwm. Waxay si gaar ah ugu habboon tahay buuxinta waxyaabaha lagu daro, budada kaarboon, budada qalalan ee dab-demiska, iyo budada kale ee saxda ah ee u baahan.

TP-PF-B11

TP-PF-B12

Laba. sifooyinka

■ Isku-xidhka cabbirka cabbiraadda weelka si loo dammaanad qaado saxnaanta saxda ah ee buuxinta.

■ Delta summada PLC xakamaynta iyo soo bandhigida shaashadda taabashada.

■ Matoorka Servo wuxuu wadaa isku-xidhka cabbiraadda cabbirka si loo dammaanad qaado waxqabadka xasilloon.

■ Kala qaybsanaanta hopper waxay noqon kartaa mid sahlan oo furan oo xiran iyada oo aan qalab lahayn, si fudud loo dhaqo.

■ Waxaa lagu dejin karaa buuxinta semi-auto iyadoo lagu bedelayo badelaha ama buuxinta otomaatiga.

■ Bir buuxda oo ah 304 walx.

■ Jawaab celinta miisaanka iyo saamiga agabka, taas oo ka gudubta dhibaatooyinka buuxinta isbeddelka miisaanka sababtoo ah isbeddelka cufnaanta alaabta.

■ Ku keydi 10 nooc oo caanaha gudaha mashiinka si hadhow loo isticmaalo.

■ Beddelida qaybaha gogoldhigga, alaabooyin kala duwan oo u dhexeeya budo khafiif ah ilaa granule iyo miisaan kala duwan ayaa la buuxin karaa.

■ Dareemka culeysku wuxuu ka hooseeyaa saxanka, si loo sameeyo buuxin degdeg ah iyo buuxin tartiib ah oo ku saleysan miisaanka horay loo dejiyay, si loo dammaanad qaado saxnaanta baakadaha sare.

■ Habka: ku rid bac/qasaca(konteenarka) mashiinka dushiisa → weelka kor u qaadida → buuxinta degdega ah, weelka hoos u dhaca → miisaanku wuxuu gaaraa nambarkii hore loo dhigay → si tartiib ah u buuxin

Saddex. Qiyaasta Farsamada

| Qaabka | TP-PF-B11 | TP-PF-B12 |

| Nidaamka xakamaynta | PLC & Shaashada taabashada | PLC & Shaashada taabashada |

| Hopper | Xakamaynta degdega ah ee goynta70L | Xakamaynta degdega ah ee goynta100L |

| Culayska Xidhmada | 100g-10kg | 1kg-50kg |

| Habka qaadashada | Iyada oo online miisaankeedu yahay; Fsi tartiib ah u buuxin | Iyada oo online miisaankeedu yahay; Fsi tartiib ah u buuxin |

| BaakadSaxnaanta | 100-1000g, ≤±2g; ≥1000g, ± 0.2% | 1 - 20kg, ≤±0.1-0.2%,>20kg, ≤±0.05-0.1% |

| BuuxintaSdhidid | 5-20waqtiyada min | 3-15waqtiyada min |

| AwoodSkor u kaca | 3P AC208-415V 50/60Hz | 3P AC208-415V 50/60Hz |

| Sahayda hawada | 6 kg/cm2 0.05m3/daqaddii | 6 kg/cm2 0.05m3/daqaddii |

| Wadarta Awoodda | 2.7KW | 3.2KW |

| Wadarta Miisaanka | 350kg | 500kg |

| Guud ahaan Cabbirrada | 1030×850×2400mm | 1130×950×2800mm |

Ikhtiyaari

Qalabka isku xirka iyo boodhka ururiyaha

Gaaska budada leh wuxuu galaa boodhka ururiyaha iyada oo loo sii marayo tuubada gelitaanka cadaadiska, balaadhinta hawada wakhtigan, xawaaraha socodka hoose wuxuu keeni doonaa qaybo waaweyn oo budo ah oo ka soocay gaaska budo oo ku dhacaya khaanadaha boodhka ee hoos yimaada cuf-jiidadka. Budo kale oo yaryar ayaa lagu dhegaa gidaarka dibadda ee shaandhada leh jihada hawadu u socoto ka dibna lagu nadiifiyo qalabka gariirku. Nadiifinta ka dib, gaasku wuxuu ka soo baxaa xagga sareka soo bixi shaandhada iyo shaandhada marada.

Codsiga

Warshadaha cuntada

Warshadaha kiimikada

Warshadaha goynta birta

Warshadaha farmashiyaha

Warshadaha qurxinta

Warshadaha quudinta

Tilmaamaha alaabta

1. Xarrago & Qurux Badan: Mashiinka oo dhan waxa laga sameeyey bir aan bir lahayn oo buuxa oo ay ku jirto marawaxad, waxa ay la socotaa jawiga shaqada ee heerka cuntada.

2. Waxtarka sare: shaandhada durbaanka kaliya ee isku laabma darajada micron waxay nuugi kartaa budo badan.

3. Xoog xoog leh: Naqshad gaar ah oo ah giraangiraha dabaysha badan oo leh awood nuugista oo ka sii xoog badan.

4. Nadiifinta ku habboon: Hal-fure budo nadiifinta gariir, noqo mid aad u hufan si aad uga saarto budada ku lifaaqan filtarka dhululubada, nadiifi boodhka si hufan.

5. Hommization: Ku darista nidaamka xakamaynta fog, u noqo mid ku habboon qalabka xakamaynta fogaanta.

6. Sawaxanka hoose: Cudbi dahaarka gaarka ah ayaa hoos u dhigaya dhawaaqa si hufan.

Halbeegga farsamada

| Qaabka | TP-1.5A | TP-2.2A | TP-3.0A |

| Heerka garaaca (m³) | 750-1050 | 1350-1650 | 1700-2400 |

| Cadaadis (pa) | 940-690 |

|

|

| Budada (kw) | 1.62 | 2.38 | 3.18 |

| Qaylada ugu badan ee qalabka (dB) | 60 | 70 | 70 |

| Dhererka | 550 | 650 | 680 |

| ballac ahaan | 550 | 650 | 680 |

| dhererka | 1650 | 1850kii | 1900kii |

| Cabbirka shaandhaynta (mm) | 325*600*1 unug | 380*660*1 unug | 420*700*1 unug |

| Wadarta miisaanka (kg) | 150 | 250 | 350 |

| Koronto kor u qaadis | 3P 380v 50HZ | ||

Nidaamka rarista

Si loo sameeyo hawlgalka mashiinka buuxinta budada ah mid ku habboon. Caadi ahaan nooc yar oo buuxinta budada ah, sida buuxinta 11L hopper, si loogu qalabeeyo nooca buunka laga soo galo; loogu talagalay buuxinta waaweyn ee hopper, sida 25L, 50L, 70L 100L hopper ee buuxinta, si ay u qalabeeyaan conveyor ama qaada vacuum ee loading, daalacashada iyo qaada vacuum ah si toos ah si ay ugu shuban hopper filler, sababtoo ah waxaa jira dareemayaal heerka gudaha gudaha alaabta wax buuxinaya, dareere ah 'diri doonaa heerka signalka. maroojiska/ faaruq-qaadiyaha u ordaya rarida. Mar alla markii sheyga hopper-ku buuxsamo, shidmahu waxa uu calaamada joogsiga joogsiga ku siin doonaa qaadaha fidiyaha/ faakuumka.

Gaadhi maroojiska

Ka kooban

1. Hopper iyo dabool

2. Dhuumaha quudinta

3. Matoorka quudinta

4. Matoorka gariiraya

5. Golaha korontada

6. Lugaha iyo castorka guurguura

Hordhac guud

Quudinta furuhu waxa ay u gudbin kartaa budo iyo walxo granul yar oo ka imanaya mishiin kale. Waa wax ku ool ah oo ku habboon. Waxay ka shaqayn kartaa iyada oo la kaashanaysa mishiinnada baakadaha si ay u sameeyaan khadka wax soo saarka. Markaa waxaa si weyn loogu isticmaalaa khadka baakadaha, gaar ahaan semi-auto iyo khadka baakadaha tooska ah. Waxaa inta badan loo adeegsadaa gudbinta agabka budada, sida budada caanaha, budada borotiinka, budada bariiska, budada shaaha caanaha, cabitaanka adag, budada bunka, sonkorta, budada gulukooska, cuntada lagu daro, quudinta, alaabta ceeriin ee dawooyinka, sunta cayayaanka, dheeha, dhadhanka, udgoonka iyo wixii la mid ah.

Tilmaamaha ugu muhiimsan

■ Ka kooban matoor laba jibaaran, matoor quudin, iyo matoor gariir, iyo koontarool kasta oo beddelaad ah.

■ Hopper waa gariir kaas oo ka dhigaya wax si fudud u qulqulaya, cabbirka hopper-na wuu beddeli karaa.

■ Qaab dhismeedka fudud ee nooca tooska ah, oo ay fududahay rakibidda iyo dayactirka.

■ Mashiinka oo dhan marka laga reebo matoorka wuxuu ka samaysan yahay SS304 si loo gaaro codsiga heerka cuntada.

■ Isku xirka tuubada quudinta iyo tuubada quudinta waxay qaataan nooca degdega ah, rakibida iyo kala diris fudud.

■ Si aad u nadiifiso alaabta la xoqay si ku habboon oo aad u naqshadeyso mashiinka si uu u noqdo: U daadi walxaha si kale, ku kaydinta alaabta gunta hoose ee tuubada hopper, ka soo saar dhammaan furayaasha.

Tilmaamid

| Tilmaamaha ugu weyn | HZ-3A2 | HZ-3A3 | HZ-3A5 | HZ-3A7 | HZ-3A8 | HZ-3A12 |

| Awoodda Dallacaadda | 2m³/saacaddii | 3m³/saacaddii | 5m³/saacaddii | 7m³/saacaddii | 8m³/saacaddii | 12m³/saacaddii |

| Dhexroorka tuubada | Φ102 | Φ114 | Φ141 | Φ159 | Φ168 | Φ219 |

| Mugga Hopper | 100L | 200L | 200L | 200L | 200L | 200L |

| Bixinta Korontada | 3P AC208-415V 50/60HZ | |||||

| Wadarta Awoodda | 610W | 810W | 1560W | 2260W | 3060W | 4060W |

| Wadarta Miisaanka | 100kg | 130kg | 170kg | 200Kg | 220Kg | 270Kg |

| Guud ahaan Cabbirrada Hopper | 720×620×800mm | 1023×820×900mm | ||||

| Dallacaadda Dhererka | Heerka 1.85M,1-5M waa la nashqadeeyey oo la soo saari karaa | |||||

| xagal dallacaadda | Heerka 45 degree, 30-60 degree sidoo kale waa la heli karaa | |||||

Khadka wax soo saarka

Buuxiyaha budada ah wuxuu ku shaqeyn karaa mashiinnada furaha, hopper kaydinta, buuxinta auger ama mashiinka wax lagu duubo, mashiinka isku dhafan ama mashiinka wax lagu duubo, mashiinka daboolka iyo mashiinka calaamadaynta si loo sameeyo khadadka wax soo saarka si loogu xidho budada ama alaabta granules ee bacaha / dhalooyinka. Khadka oo dhan wuxuu ku xirmi doonaa tuubo silikoon oo dabacsan mana yeelan doono wax boodh ah oo ka soo baxa, ilaali jawiga shaqada ee aan boodhka lahayn.

Wax soo saarka iyo habaynta

qolka bandhiga warshad

Aqoon-is-weydaarsiga wax-soo-saarkayagu wuxuu leeyahay xirfad-yaqaanka habaynta ee noocyada kala duwan ee shaqada, shaqaalaha alxanka, laambada-tooska, shaqaalaha ururinta, polisher, iyo nadiifiyeyaasha, shaqaalaha baakadaha. Shaqaale kasta si adag ayaa loo tababaray ka hor inta aanu xilka qaadin. Kala-soocidda shaqada habayntu waa caddahay, xidhiidh kasta oo farsamayntuna waa la dammaanad qaaday, markaa dhammaan mishiinka isku-dhafka ah waa la dammaanad qaaday.

Shanghai Tops Group Co., Ltd. Waxaan ku takhasusay dhinacyada naqshadeynta, wax soo saarka, taageerada iyo u adeegidda line-soo-saarka dhamaystiran ee mishiinada noocyada kala duwan ee budada iyo alaabta granular, bartilmaameedkayaga ugu weyn ee shaqada waa in aan bixino alaabta kuwaas oo la xiriira warshadaha cuntada, warshadaha beeraha, warshadaha kiimikada, iyo farmashiyaha beerta iyo in ka badan. Waxaan qiimeynaa macaamiisheena waxaana u heellan inaan sii wadno xiriirka si aan u hubinno qanacsanaanta joogtada ah oo aan u abuurno xiriir guul-guul ah.